MR. JO Tecbond-EMV — Solve Handling, Positioning & Controlled Insulation Needs in Electrical Work

MR. JO Tecbond-EMV — Solve Handling, Positioning & Controlled Insulation Needs in Electrical Work

Problem (practical site pains)

- Low-viscosity adhesives run off small mounts or bridge across contacts, causing shorts or rework.

- Heavy adhesives are hard to control for small components and lead to messy joints.

- You need a balance between flow (to wet surfaces) and staying where you apply (to avoid contamination).

Why EMV is the right fix

MR. JO Tecbond-EMV is a medium-viscosity 100:10 epoxy designed for controlled flow — it wets and bonds well, but does not run or creep onto adjacent components. That makes it perfect for many electrical bonding tasks where positional stability and good dielectric performance are both needed.

Real-world use cases

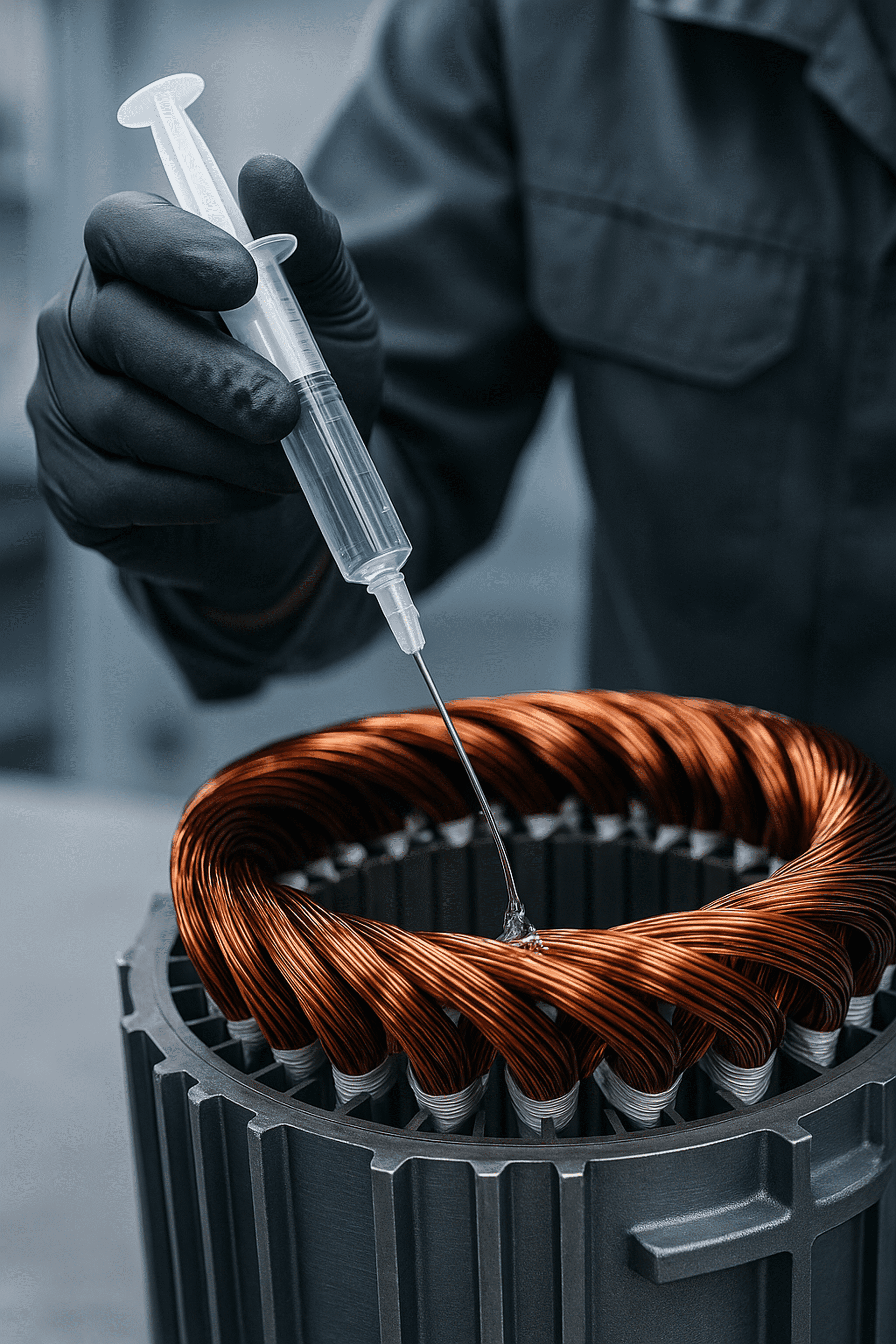

- Anchoring and potting of small transformers, coils and connectors where overflow must be avoided.

- Gluing heat-sinks or mechanical supports to PCBs where adhesive should not wick into tracks.

- Small motor repairs and component mounting where controlled coverage is required.

- Gap-filling on assemblies that are slightly irregular but can’t tolerate sag or flow.

How to use — job-ready workflow

- Prep: Clean and, where needed, slightly abrade bonding surfaces for better mechanical keying. Remove oils and dust.

- Weigh & mix: 100 : 10 by weight — mix thoroughly to homogeneity.

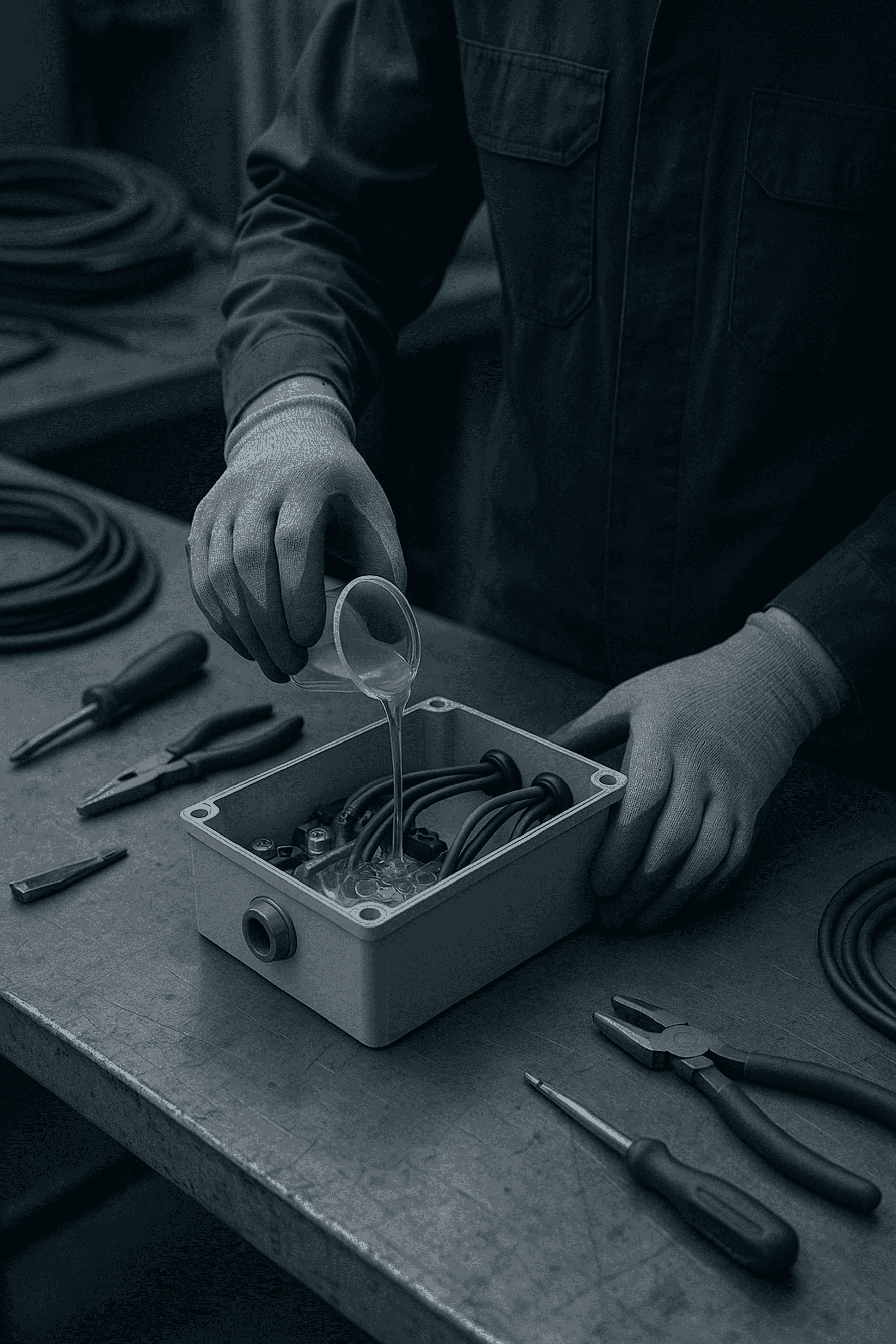

- Apply: Use syringes, dispensers, or spatulas. EMV allows relatively precise placement without sags.

- Optional impregnation: For shallow gaps, EMV will wet-in; for deep impregnation use ELV instead.

- Cure & test: Cure as per TDS, then verify insulation resistance and mechanical bond.

Dos & Don’ts

Do:

- Use EMV where you need visual control and no run-off.

- Use dispensers or syringes for consistent application.

- Mask nearby contacts and tracks as a precaution.

Don’t:

- Don’t expect EMV to fully impregnate dense windings — use ELV for deep capillary action.

- Don’t over-apply; excess increases cure time and cleanup.

- Don’t skip post-cure checks for high-voltage parts.

Troubleshooting

- Adhesive not wetting metal? Re-clean or abrade surface; remove oxidation.

- Adhesive sagging slightly? Check ambient temperature (higher temps lower viscosity); reduce batch size or cool materials.

- Residue on solder joints? Mask joints or apply careful bead-by-bead dispensing.

EMV solves the common problem of “I need good electrical adhesion but don’t want this stuff running into unwanted areas.” It’s the practical middle ground — controlled wetting with positional stability.

Leave a Reply