The fast, no-sag glass finish that saves curved and vertical art

The fast, no-sag glass finish that saves curved and vertical art

Hook — the artisan’s late-night panic

It’s late. Ramesh, a wood sculptor, has just finished the final sanding on a small curved figurine commissioned for a gallery show tomorrow. He needs a high-gloss, glass-like coat that won’t drip down the delicate curves or obscure the fine carving. He’s tried other resins that either ran into the crevices, left tacky spots, or took hours to stabilize — costing him time and reputation.

If this feels familiar, you’re not alone. Curved and vertical surfaces are where many glossy finishes fail — unless you use the right Artglue.

The problem — what usually goes wrong

Artisans working on curved, ornate, or vertically oriented pieces face three recurring problems:

- Sagging & runs: Fast movement of the liquid coat under gravity creates drips or uneven thickness on curves and edges.

- Short open/working window mismatch: Some resins cure too slowly and run; others cure too fast and don’t level properly.

- Surface loss of detail: Heavy runs or overwork can fill and blur fine carving or inlay details that define the piece.

These lead to rework, wasted material, missed deadlines, and unhappy clients.

The solution — why CG50i was designed for this job

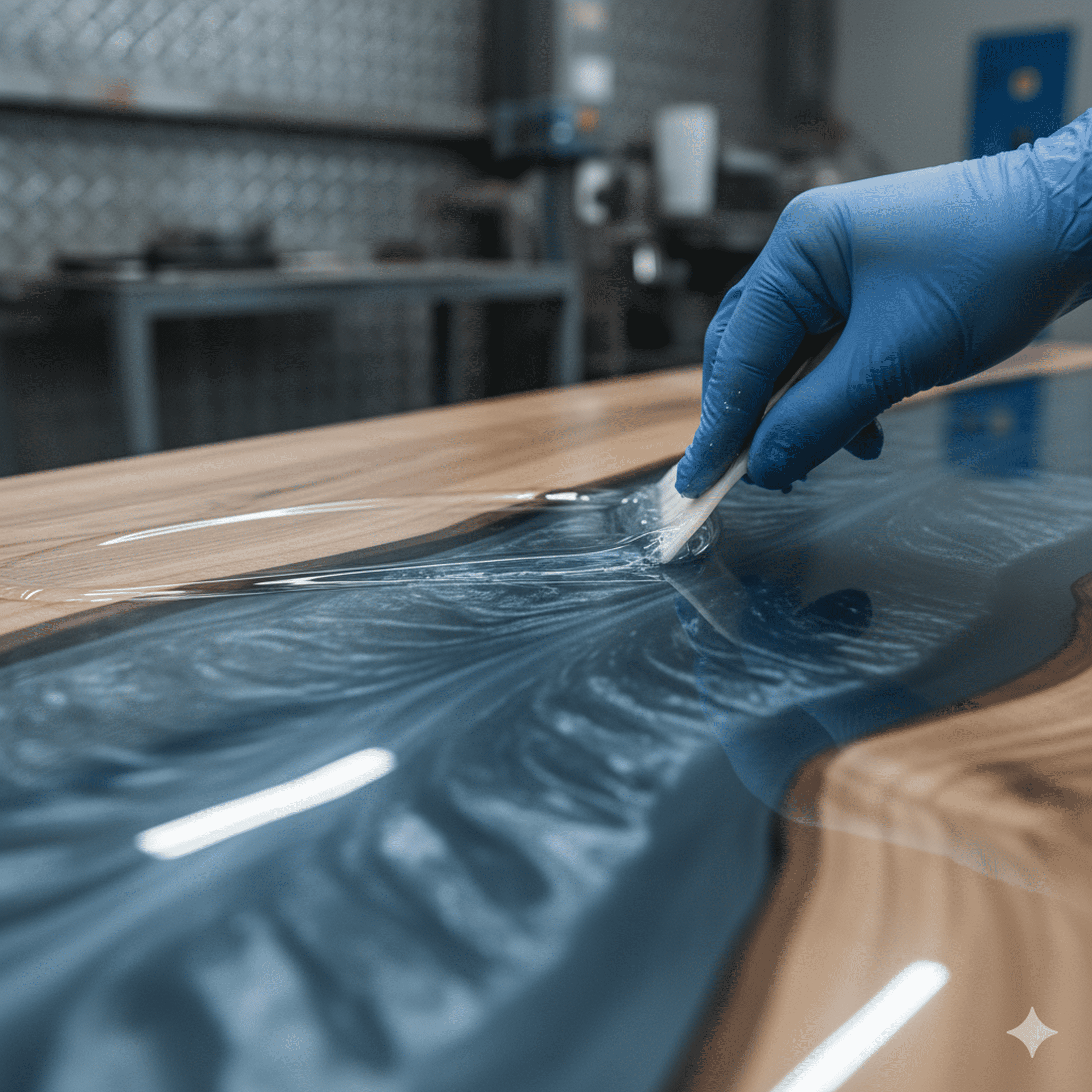

MR. JO Artglue — CG50i is the fast-curing, low-sag member of the Artglue family. It’s formulated so small mixed batches gel quickly enough to stop sagging on curves, yet remain fluid long enough to self-level and give a mirror-like finish.

Key design choices:

- Fast gel time to prevent dripping on vertical/curved surfaces.

- Controlled flow & leveling so the surface finishes glossy without brush marks.

- Hard, durable cure for abrasion resistance and long life.

In short — CG50i is the product Ramesh needs to get gallery-quality glossy finishes on curved sculptures, vases, and ornamentals without the stress.

What CG50i actually solves (real benefits)

- No sag on curves — quickly reaches a tack where gravity can’t pull it down.

- Fast turnaround — dries and stabilizes in minutes, curing fully far sooner than slow resins.

- Cleaner edges and fine detail retention — because it sets before it runs into carvings.

- Professional gloss & hardness — gives a deep, glassy surface that polishes beautifully.

- Lower rework & waste — less sanding, fewer rejected pieces.

Job-ready workflow (practical how-to)

- Prepare: Ensure the piece is dust-free, fully sanded, and dry. Mask any areas (base, joints) you don’t want coated.

- Measure & mix: Mix small batches as recommended on the TDS (small batches reduce heat/exotherm and let you control gel). Stir gently to avoid air.

- Apply: Pour or spread a thin, even coat with a soft brush or spreader. For very intricate curves, a small disposable brush or syringe helps.

- Level: Let surface tension do the work — CG50i levels quickly. If necessary, use a heat-gun lightly (at safe distance) to pop minor bubbles — short bursts only.

- Cure: Allow initial gel/skin to form (fast with CG50i) — this prevents runs. Full cure per TDS; times are shorter than slower variants.

- Finish: Light sand and second coat if extra depth desired. CG50i’s speed means multiple thin coats finish faster than one thick slow coat.

Dos & Don’ts — field wisdom

Do:

- Work in small batches for curved/vertical pieces.

- Mask contact points and hardware to prevent adhesion where you don’t want it.

- Keep the workshop at recommended temp to avoid too-fast or too-slow cure.

Don’t:

- Don’t overmix (which brings in bubbles).

- Don’t pour huge volumes on a small curved piece — thin coats are better.

- Don’t skip a quick bubble pass with gentle heat if bubbles appear.

Troubleshooting (quick fixes)

- Too many bubbles? Use slower, quieter stirring; warm the mixed batch slightly (not hot) to reduce viscosity then pour; use light passes with a heat gun to pop bubbles.

- Minor runs occurred? After initial cure, trim/sand and recoat — CG50i sands well once cured.

- Surface dry tacky? Possibly incorrect mix ratio or low temp — check TDS and ambient conditions.

Artisan scenario — Ramesh’s turnaround

Ramesh mixed small batches of CG50i, poured a thin coat, and within minutes the surface began to stabilize without running. He finished two thin coats that evening, left the piece to cure, and the gallery collected a flawless sculpture with deep gloss and crisp carvings the next day. No panic, no rework — just a satisfied artisan and client.

Final takeaway — who should use CG50i

If your work involves curved, vertical or highly detailed surfaces and you need a fast, glossy, non-sag finish with quick turnaround, MR. JO Artglue-CG50i is the smart choice. It’s the go-to for artisans who value finish quality, speed, and predictable results.

Leave a Reply