Cracks, Delamination & Downtime: How Composite Makers Found a Reliable Lamination Partner

When you walk into a composites workshop, you’ll often hear the same concerns repeated:

- “This laminate didn’t bond well to the gel coat.”

- “We’re seeing weak layers after demoulding.”

- “The adhesive ratio has to be so precise, otherwise it either stays tacky or becomes brittle.”

For fabricators working with moulds, backing layers, and laminates, the bonding system is the backbone of the whole job. One wrong choice—and weeks of effort can end up wasted.

The Problem: Unreliable Bonds in Laminations

Traditionally, many workshops rely on LY556/HY951 type systems. While effective, they come with pain points:

- Sensitive mixing ratios: Even small deviations cause curing issues.

- Limited pot life: Leaves fabricators racing against the clock.

- Inconsistent adhesion with gel coats: Especially with new-age epoxy-based gel coats.

- Risk of weak interlaminar bonding: Leading to cracks, delamination, or dimensional instability in moulds.

When your entire mould is at stake, these aren’t just minor inconveniences—they’re potential project disasters.

The Solution: A Lamination System That Understands Composite Makers

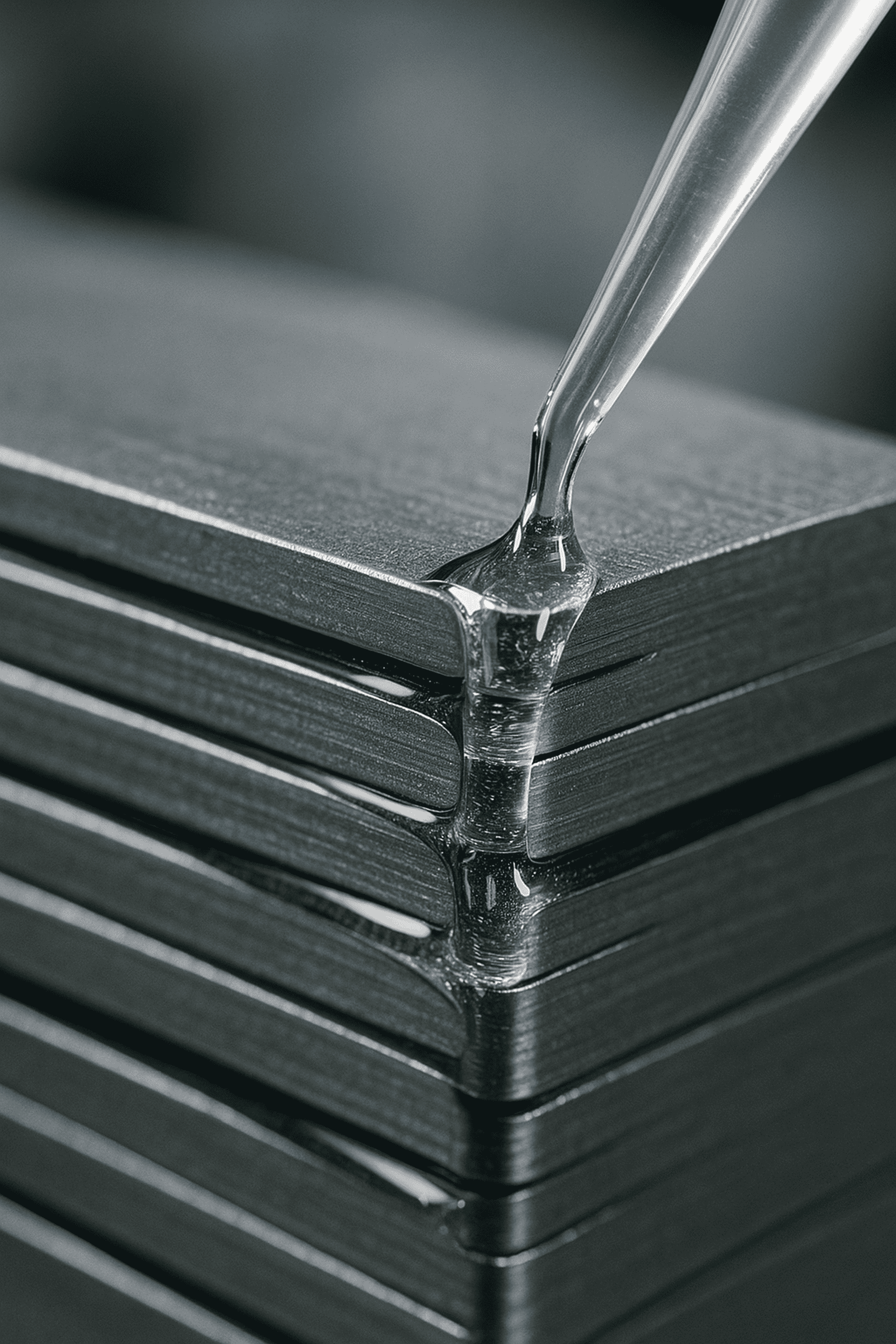

That’s why we created MR. JO Tecbond – ELAM, a 100:10 lamination epoxy adhesive built for composite shops that demand both strength and reliability.

Engineered to back up and bond seamlessly with the MR. JO Gelkot series, ELAM solves the three key pain points composite makers face:

- Consistency Every Time – The 100:10 mixing ratio is simple, forgiving, and eliminates the stress of micro-errors during batching.

- Superior Interlaminar Strength – Ensures that gel coat, backing, and laminates behave as one integrated structure. No weak planes.

- Practical Workability – Balanced pot life gives fabricators enough time to work, without risking tackiness or delays.

Why Fabricators Trust ELAM

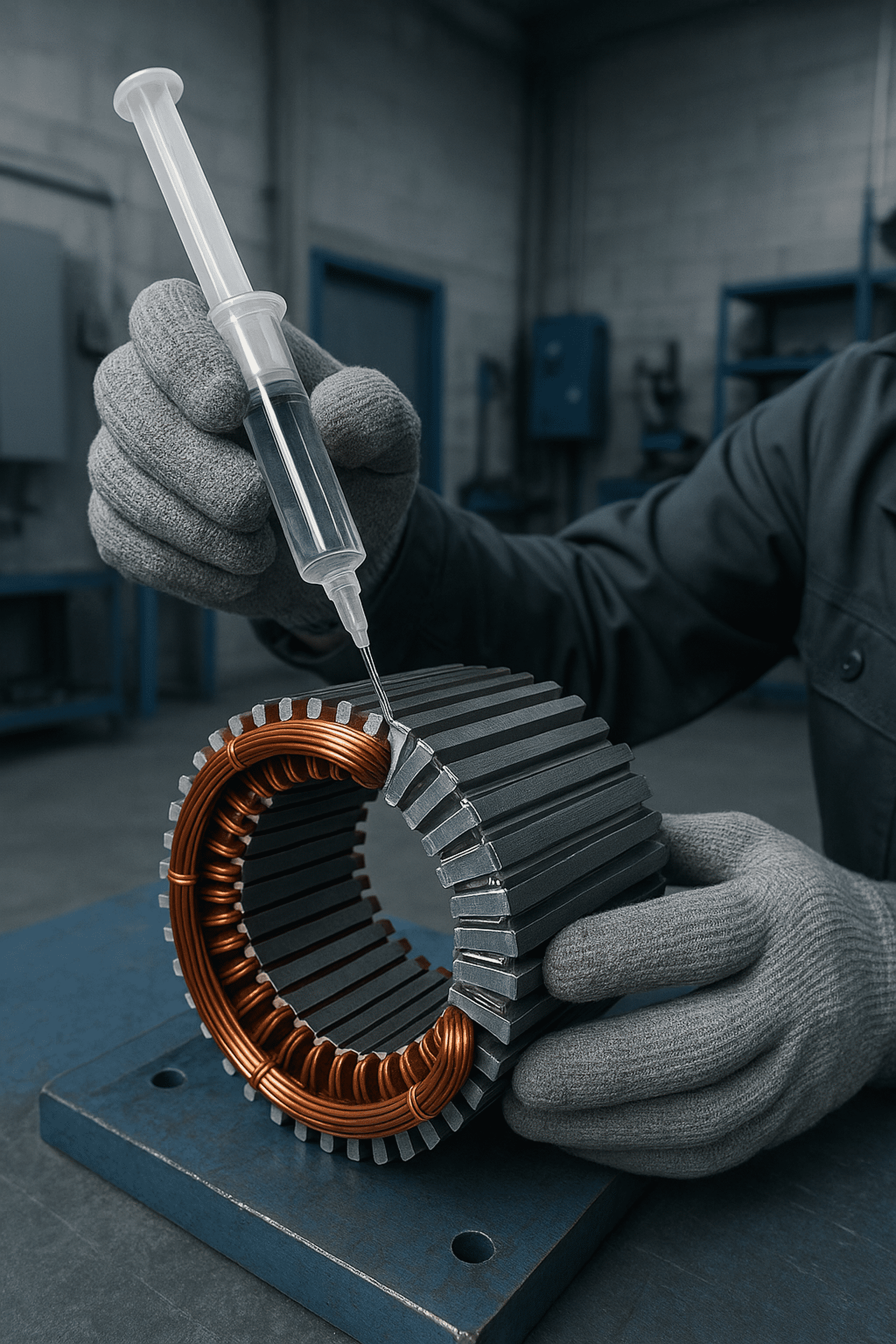

- Designed to pair with MR. JO Gelkot BLU, WHT, and BLK – ensuring perfect bonding right from the gel coat layer.

- Trusted for mould making, laminations, and composite backings.

- Proven performance comparable with industry standards like LY556/HY951—but at a more accessible and workshop-friendly level.

A Workshop Story

One of our composite clients in Morbi was facing repeated issues with delamination in sanitaryware moulds. They had been using a generic system, but cracks appeared within weeks of use. After switching to MR. JO Tecbond – ELAM with MR. JO Gelkot-BLU, they reported:

- Zero delamination after repeated thermal cycles.

- Smooth compatibility with their existing workflow.

- Confidence to scale up production without fear of rejection.

Their words summed it up best:

“ELAM feels like it was made for us—not just another adhesive, but a solution that understands the reality of our workshop.”

In composites, your mould is your foundation. Compromise on the adhesive, and you compromise on everything built on it.

MR. JO Tecbond – ELAM isn’t just another lamination adhesive—it’s the problem-solver for fabricators who value strength, consistency, and peace of mind.

Leave a Reply