How MR. JO Marblevacuum Makes Stone Blocks Stronger, Slabs Cleaner, and Processing Faster

Used Across: Silvassa, Rajasthan, and other advanced marble and stone processing clusters

Product: MR. JO Marblevacuum – a two-component, very low-viscosity, solvent-free epoxy system for vacuum impregnation of stone blocks

🧩 The Problem: Cracked Blocks, Porous Stones, and Post-Cutting Headaches

Before a block ever becomes a polished slab, many processors are already dealing with problems hidden deep inside:

- Internal cracks and porosity that weaken the slab when cut

- High reject rates due to invisible internal voids

- Heavy post-processing work — including labor-intensive crack filling (Marblefill) and coating (Marblekot) — to make slabs usable

- A growing need to maintain a natural look, especially with decorative stones where customers avoid epoxy gloss finishes

Traditional polyester systems shrink, trap air, release strong odors, and often don’t reach fine pores — resulting in poor bond strength and uneven surfaces.

🧑🔧 The User: Modern Block Processors Investing in Upstream Quality

MR. JO Marblevacuum is used by stone block processors, especially in Silvassa and Rajasthan, who want to fix defects before the first cut. It’s a choice made by processors with access to vacuum-assisted processing who aim to:

- Stabilize fragile blocks

- Minimize slab-level epoxy rework

- Offer a more natural, uncoated surface to discerning buyers

This shift upstream ensures stronger slabs, fewer losses, and lower labor costs post-cutting.

🛠️ The Application: Vacuum In, Strength Out

Where used: Full marble or stone blocks (before cutting into slabs)

Resin:Hardener Ratio: 100:33 PBW

Pot Life: 8–10 hours (ideal for extended vacuum sessions)

Coverage: Approx. 30–50 kg per block (depending on porosity)

Curing: Ambient temperature — no heating required

✅ Application Method:

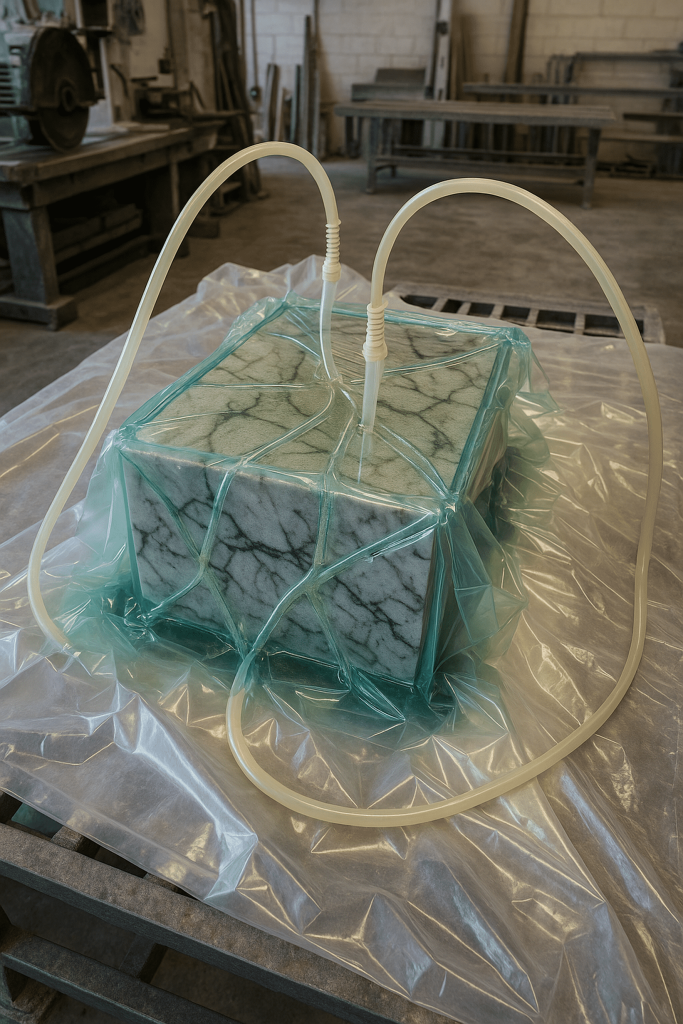

- The stone block is placed securely, and a large PVC vacuum bag is laid over it, covering all sides.

- A vacuum is drawn from one end of the bag to remove air from the block’s pores.

- MR. JO Marblevacuum epoxy is introduced from the other end, allowing it to flow and impregnate all internal cracks and voids under vacuum pressure.

- Once impregnation is complete, the vacuum is released, and the block is left to cure naturally at room temperature.

This long open time allows full penetration into microcracks and fine capillaries, ensuring thorough reinforcement.

📈 The Result: Cleaner Slabs, Less Rework, Better Profit

Once the block is cut into slabs, the advantages of MR. JO Marblevacuum become clearly visible:

- Slabs are more stable, with fewer edge cracks or breakage

- Surface porosity is sealed, reducing the need for slab-level filling

- Polishing is smoother, with no bond failures or pop-outs

- In decorative and premium stones, processors may skip coating altogether to retain a natural look

User Feedback:

“Good filling capacity, no bond failures in polishing, excellent clarity. Since it’s solvent-free, there’s no odor and no health concern for the team.”

🧪 Technical Edge: Designed for Deep Penetration and Cleaner Processing

Unlike polyester-based or conventional epoxies, MR. JO Marblevacuum offers:

- Ultra-low viscosity for complete absorption into even hairline cracks

- Clear, colorless finish, suitable for light and premium stones

- Zero solvents, making it safer and more eco-friendly

- Long pot life (8–10 hours) — ideal for block-scale vacuum sessions

- No shrinkage, no yellowing, and excellent mechanical integrity

- No need for heating, avoiding material wastage or fast gelling

🔗 Paired Products: When You Want to Go Further

Since Marblevacuum addresses internal porosity before cutting, other surface-level products may not be needed. However, in case of higher-end finishing:

- MR. JO Marblewrap is not required when Marblevacuum is used

- MR. JO Marblefill is typically unnecessary unless surface-level cracks persist

For high-gloss coating (optional), MR. JO Marblekot or Artcast-CC33 may be used post-slab cutting

✅ Conclusion

MR. JO Marblevacuum represents a smarter approach to stone processing: fixing the block before cutting the slab. By strengthening from the inside out, it eliminates the need for time-consuming repairs and coatings later, helping processors improve slab yield, reduce cost, and meet modern customer preferences for natural finishes.

Leave a Reply