MR. JO Gelkot-BLU : Blue Epoxy Gelcoat for Ceramic Models, Molds & Composite Tooling

MR. JO Gelkot-BLU : Blue Epoxy Gelcoat for Ceramic Models, Molds & Composite Tooling

MR. JO Gelkot-BLU is a high-performance two-component blue epoxy gelcoat designed specifically for applications that demand precision, surface durability, and visual contrast. It is ideal for mold making, composite tooling, foundry patterns, and working models in industries like ceramics, engineering, and prototyping.

Formulated with high viscosity and a thixotropic nature, this solvent-free system cures rapidly at room temperature, creating a smooth, tough, chemical-resistant skin that holds its shape and finish, even under repeated use.

🧩 The Challenge at Many Sites

Waterproofing failures often stem from an unexpected source: the water added during mixing. On-site dilution with hard water, unmeasured quantities, or inconsistent mixing can compromise the final film.

Even the best epoxy systems can falter if a careless mix leads to chalky coatings, patchy curing, or poor bonding. Especially in large projects, controlling field variables becomes a challenge.

🔵 Key Features

🎯High Viscosity & Thixotropic Flow – Stays put on vertical or contoured surfaces without sagging.

⏱Fast Room-Temperature Curing – Enhances speed of production with no need for ovens.

💪Hard, Durable Finish – Abrasion-resistant, polishable, and built for long-term use.

🧪Excellent Chemical & Thermal Resistance – Withstands harsh environments typical in tooling and casting.

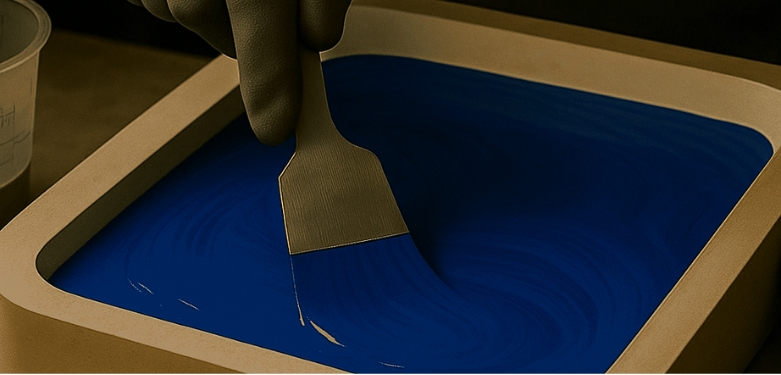

🖌Brush or Spatula Application – Easy to apply even on fine-detail or complex shapes.

🌱 Solvent-Free – Ensures a safer, low-odor, and cleaner working environment.

📐 Technical Properties

| Property | Value |

| Color | Blue |

| Mixing Ratio (PBW) | 100:14 |

| Pot Life @ 25°C | 20–30 minutes |

| Mixture Consistency | Thixotropic paste |

| Optics | Opaque |

| Cure Method | Room temperature |

🧰 Recommended Applications

🧱 Working Models for Ceramics

Ideal for the sanitaryware industry, tile prototypes, and model development.

🔵 Gelcoating for Laminating Molds

Provides a smooth, controlled surface for subsequent fiberglass or carbon fiber layups.

🧩 Negative Molds & Foundry Patterns

Accurate replication, durable edges, and high-temperature performance.

📏 Copy Milling & Tool Templates

Maintains dimensional stability and visibility in automated or manual machining.

🔧 Mold Repairs & Surface Rebuilds

Recoat or touch up worn gelcoats to extend mold lifespan and restore finish quality.

🧪 Why Choose MR. JO Gelkot-BLU?

- Vivid Blue Contrast

Makes surface imperfections easy to spot and enables visual checks during fabrication. - Clean Application

Its paste-like flow avoids drips and runs — ideal for intricate or vertical geometry. - Fast Turnaround

Rapid cure at room temperature keeps production timelines on track. - Excellent Adhesion

Sticks reliably to epoxy-compatible substrates without delamination or air entrapment. - Long-Term Performance

Maintains gloss and strength over repeated demolding and temperature cycles.

🛠️ Application Instructions

- Surface Prep

Ensure the master/model is clean, dust-free, and treated with an appropriate release agent. - Mixing

Combine 100 parts resin to 14 parts hardener (by weight) and stir until homogeneous. - Application

Apply by brush or spatula in a 1–2 mm thickness. Avoid overly thick spots to prevent trapped air or improper cure. - Curing

Allow to cure at ambient temperature in a clean, shaded area free from dust. - Topcoat or Layup

Laminate over with composites or use as-is for surface protection once fully tack-free.

📦 Packaging Options

- Convenient kits designed for manual application.

- Bulk quantities available for industrial use or automated shops.

⚠️ Storage & Handling

- Store in cool, dry, sealed containers between 18–25°C.

- Use PPE such as gloves and goggles during mixing and application.

- Refer to MSDS for safe handling, disposal, and first aid measures.

delivers a reliable, durable, and visually sharp solution for mold surfaces, laminating tools, and working prototypes. Whether in ceramics, composites, or engineering molds, its blue color aids visibility, its fast-cure formula improves throughput, and its tough epoxy base ensures every mold stays sharp and strong, use after use.

Leave a Reply