MR. JO JH 1001 — The Flooring Hardener That Keeps Projects On Schedule (and Looking Great)

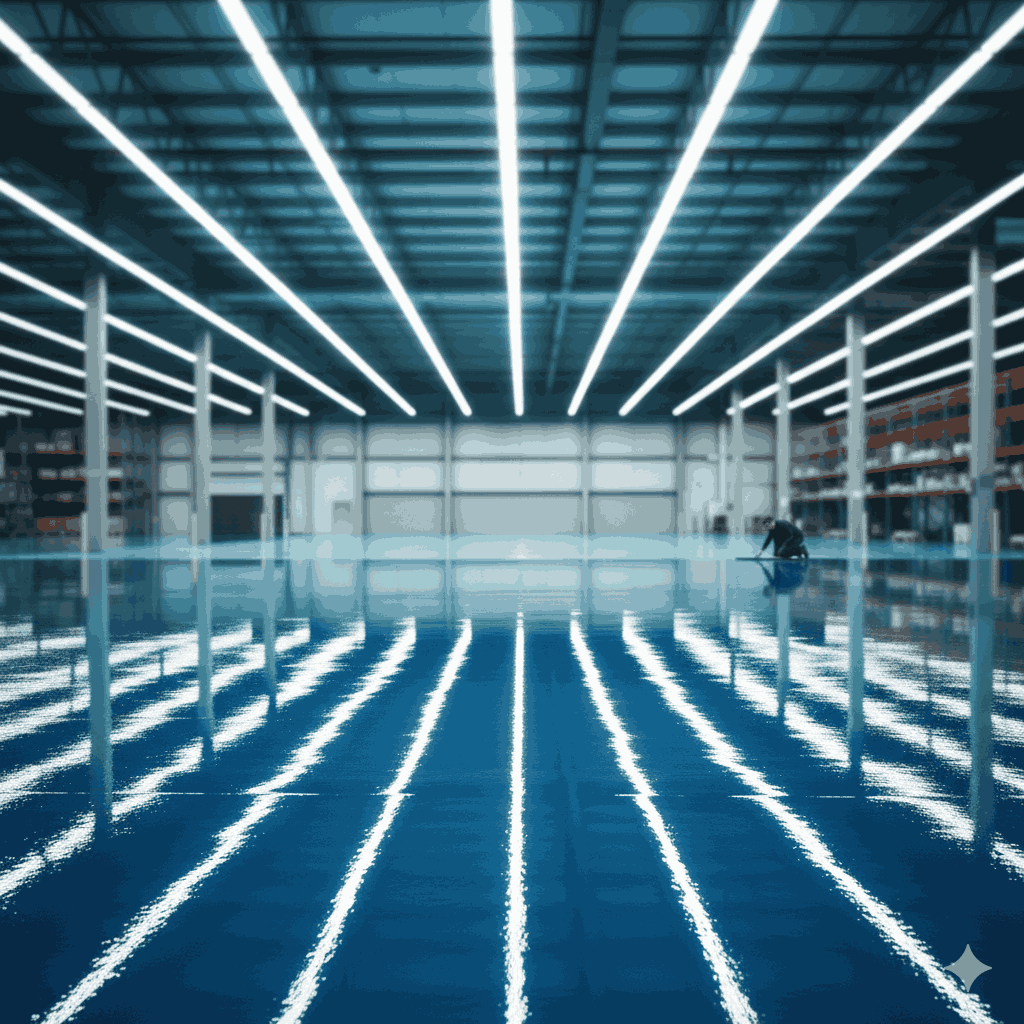

Ravi, site supervisor on a busy commercial fit-out, had three things he couldn’t compromise: a high-gloss finish, no blushing in the tropical humidity, and the client’s deadline. One wrong hardener choice and the floor would be a costly rework. JH 1001 is the hardener Ravi reaches for in that exact situation — a purpose-built, blush-resistant flooring hardener that balances working time, surface finish and durability.

The problem: glossy floors in hot, humid sites are deceptively hard work

Commercial floors need more than mechanical strength. In practice teams struggle with:

- Blushing (amine blush) in hot, humid climates that ruins gloss and adhesion of subsequent coats.

- Inconsistent pot life or curing that makes large pours unpredictable.

- Poor chemical and wear resistance if the hardener is too “soft.”

- Logistics headaches when only 200-kg drums are available and teams need small, site-friendly packs.

If you’re preparing specification text, scheduling applicators, or supervising the pour, these are real pain points — not lab hypotheses.

The solution: where JH1001 fits

JH 1001 is a low-viscosity, modified polyamine hardener designed as a specialty flooring grade (typical mix ~50 phr with standard Bis-A epoxy resins). Its working profile is tuned for hot, humid conditions and for producing high-gloss, blush-resistant finishes.

Key technical pointers:

- Recommended phr: ~50 (follow TDS for exact stoichiometry)

- Viscosity: 100–500 mPa·s — wets substrates well and helps achieve a smooth, glossy film.

- Amine value: ~250–300 mg KOH/g — balanced reactivity for flooring systems.

- Pack sizes: available in project-friendly packs (1 / 5 / 10 / 20 kg) — reduces waste and handling problems on site.

How JH 1001 solves the problems — practical benefits

- Blush resistance: Modified chemistry reduces surface exudation of amine salts in humid conditions, producing persistent gloss and better overcoat adhesion. In tropical sites you’ll see far fewer cloudy patches and less rework.

- ** predictable pot life:** At 25 °C JH 1001 gives a stable work window for medium-sized pours — enough time to lay, de-air and finish without unnecessary rush.

- Good film properties: Properly cured systems show excellent hardness, abrasion resistance and chemical tolerance expected of commercial floors.

- Site-friendly packs: Buying in the right pack size avoids dosing mistakes and makes logistics simple — a real relief for smaller contractors.

How to use it — jobsite workflow (practical)

- Substrate prep: Mechanically prepare concrete to the specified profile, remove dust and laitance. Moisture should be within acceptable limits (use moisture meter).

- Resin choice: JH 1001 works well with Jpoxy unmodified and modified resins (e.g., JR 3013/JR 3000 families). Follow the resin TDS for exact phr and mixing sequence.

- Mixing: Measure accurately. Add JH 1001 to resin, mix slowly to avoid air. If you need to accelerate cure for colder conditions, blend with JH 1010 (small percentage) — but always trial first.

- Application: Roller, not brush, for topcoats; squeegee/trowel for screeds per system. Avoid overworking; allow trapped bubbles to escape.

- Curing & recoat: Follow TDS windows; JH 1001 gives predictable overcoat times in standard ambient conditions.

Troubleshooting — quick fixes

- Excessive blush on topcoat? Improve ventilation, warm the substrate, or ensure you’re using JH1001 (blush-resistant grade). If still present, wipe with isopropyl alcohol (test first) and recoat when dry.

- Too fast set/short pot life on a hot day? Reduce batch size, work in shaded area, or slightly cool materials (store resin/hardener in cool place).

- Sags or run marks? Check viscosity and film thickness — reduce material thickness or switch to a slightly higher-viscosity build coat before the finish coat.

Safety & QA notes

- Use PPE: nitrile gloves, goggles, and appropriate ventilation.

- Always run a site trial (1–5 kg) with your actual substrate, pigment, filler and environmental conditions before full-scale work.

- Store in factory packs; product shows long shelf life in company packaging but follow date codes.

Bottom line

For hot, humid projects where finish and delivery schedule matter, JH 1001 is the reliable starting point: blush-resistant, user-friendly, and designed for real site conditions. Choose project packs, run a small site trial, and if the job needs faster turnarounds in cold weather, bring JH 1010 into the mix.

Leave a Reply