MR. JO JH 1027: Tetraethylenepentamine (TEPA) – High Functionality Hardener for Stronger, Faster Epoxy Systems

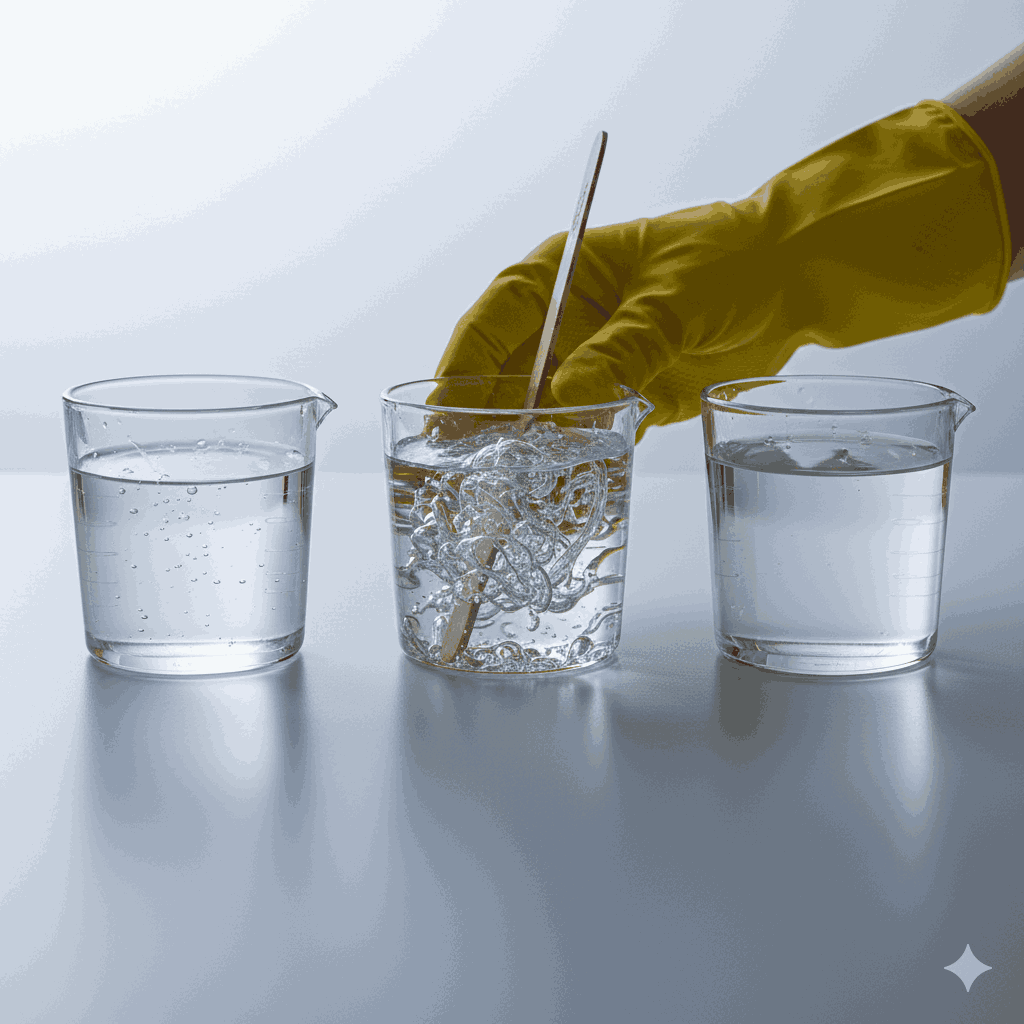

When epoxy systems demand higher crosslink density, faster cure, and improved chemical resistance, formulators look for curing agents with more reactive sites. JH 1027 (TEPA – Tetraethylenepentamine) fits that role perfectly as a multi-functional aliphatic amine.

Key Technical Data

- Chemical Type: Tetraethylenepentamine (linear polyamine)

- Amine Value (mg KOH/g): 1,300 – 1,400

- Viscosity @ 25°C (mPa·s): 10 – 25

- Color (Gardner): ≤1

- Density @ 25°C (g/cc): 0.98 – 1.00

With five reactive amine hydrogens, TEPA enables faster cure and harder, more chemically resistant epoxy networks compared to lower-functionality amines like TETA (JH 1036).

Typical Applications

- Adhesives & bonding pastes needing strength and chemical resistance

- Fast-cure primers & coatings for metal, concrete, and industrial surfaces

- Solvent-free floorings & mortars where speed and strength matter

- Marine & protective coatings in aggressive environments

- Civil engineering grouts & injections needing rapid set

Formulation Advantages

- Works well with bisphenol-A and bisphenol-F epoxy resins.

- Can be blended with TETA (JH 1036) to balance cure speed and pot life.

- Compatible with accelerators (e.g., AEP, BDMA) for fine-tuning reactivity.

- Provides a higher-functionality option when TETA alone is not enough.

Why JH 1027?

While TEPA is globally available from big chemical players, it’s rarely accessible in small, flexible pack sizes for R&D labs, niche users, and mid-size manufacturers. JH 1027 bridges this gap by offering consistent quality, standard packaging, and even small-batch supply — empowering users to experiment and scale with confidence.

Leave a Reply