MR. JO JH 1055 — Fast primer & injection-grout hardener that gets the job back to work

MR. JO JH 1055 — Fast primer & injection-grout hardener that gets the job back to work

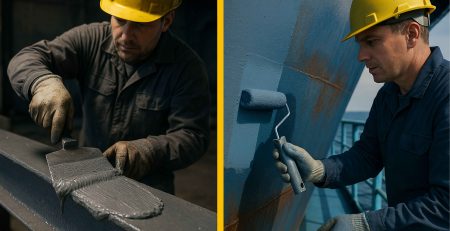

The forklift driver skidded into a cracked service bay and tore a chunk out of the concrete floor. The operations manager needed that lane back by tomorrow morning — no excuses. For jobs like this, where speed, bond and early load capacity matter, contractors reach for JH 1055: a low-viscosity, fast-reacting modified polyamide hardener made for primers, repair mortars and injection grouts.

This post is a practical, problem-solving guide: what goes wrong on urgent repair jobs, why JH 1055 fixes them, how to use it on site without surprises, and simple troubleshooting checks to avoid callbacks.

The real problem on emergency repair jobs

Typical failure modes that turn a quick repair into a headache:

- Long downtime because the repair system won’t reach early strength fast enough.

- Poor substrate wetting that causes delamination or weak bonding.

- Difficulty pumping or injecting grout because the hardener is too viscous or sets too slowly.

- Logistics pain when only large drums are available and applicators need small, precise quantities.

JH 1055 is built to solve those pain-points in real site conditions.

Why JH 1055 is the practical choice

Technical snapshot:

- Typical phr: ~40 (follow resin TDS for exact stoichiometry)

- Viscosity: 350–750 mPa·s @ 25 °C (low-viscosity range)

- Amine value: 410–490 mg KOH/g (robust reactivity)

- Color (Gardner): ≤10; Density: ~0.95–1.0 g/cc

- Primary uses: Primers, injection grouting, repair mortars, primers for patch systems.

Advantages on-site:

- Fast reactivity: Quick tack-free and early strength development — ideal for short turnarounds.

- Low viscosity: Excellent wetting of substrate and easy pumpability for injection grouts.

- Good adhesion: Modified polyamide chemistry bonds well to prepared concrete and common substrates.

Project packs: Available in site-friendly sizes so teams order what they need and avoid drum logistics.

Jobsite workflow — step-by-step

- Substrate prep: Remove loose concrete, oil, and dust. For best adhesion use mechanical profiling (grinding/shot-blast) to the specified profile.

- Select resin partner: JH 1055 pairs well with JR resins (e.g., JR 3013 / JR 3000). Follow the resin TDS for exact phr and mixing sequence.

- Measure & mix: Accurately weigh resin and JH 1055. Mix gently at low speed until homogeneous — low viscosity helps avoid trapped air. For injection grouts use a pump-compatible mix.

- Apply primer: A thin primer coat improves bond for subsequent mortar or grout. Because JH 1055 wets well, coverage is efficient.

- Pump/inject mortar: For injection grouting, keep batch sizes small and continuous feed to the pump. Use recommended filler gradations to control bleed and strength.

- Cure & traffic: Expect early strength (hours rather than days) depending on temperature and batch size — consult the system TDS for load timelines.

Common field issues & fixes

- Too-fast set in warm weather: Reduce batch size, cool components (store in shade), or work in shaded area. Plan logistics — small batches are safer.

- Pump blockages with mortars: Use recommended filler grading and check filler moisture. Pre-wet or pre-screen fillers if needed.

- Incomplete bond: Recheck surface profile and cleanliness. Primer coat with JH 1055 improves adhesion — don’t skip it.

- Excessive blush or tack: Rare with JH 1055, but if present ensure adequate ventilation and correct mix ratios.

Safety, QA & best practice - Site trials: Always run a 1–5 kg mock-up with your actual substrate, filler and ambient conditions. Record pot life, tack-free time and early hardness.

- PPE: Gloves, goggles and suitable ventilation. Follow SDS for handling and disposal.

- Packaging: Use project-sized packs to eliminate dosing errors and simplify logistics. MR. JO packs reduce waste and make emergency repairs practical.

Bottom line

When the clock is tight and the floor must be back in service fast, JH 1055 delivers the two things that matter most: speed and dependable bond. Use it for primers, injection grouts and repair mortars to turn emergency calls into one-day fixes — provided you plan batch sizes, prep the substrate and run a quick site trial.

Leave a Reply