MR. JO JH1052 — The filler-friendly primer & repair hardener for heavy-build mortars

MR. JO JH1052 — The filler-friendly primer & repair hardener for heavy-build mortars

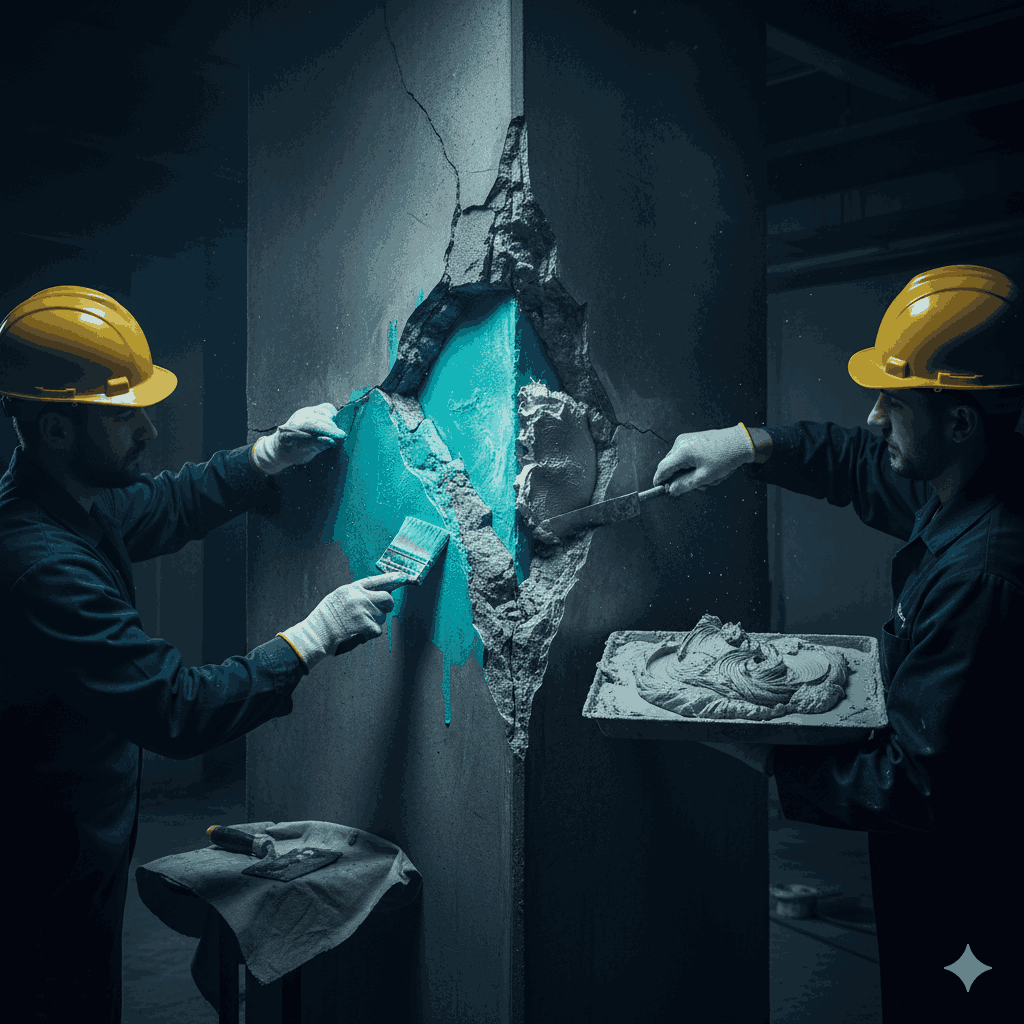

When a factory floor shows up with potholes that need a trowelled repair and the client wants a dense, durable screed that won’t dust out in a month, the conversation quickly becomes about filler loading, workability and adhesion — not lab jargon. That’s the exact job JH 1052 was designed for: a medium-viscosity, modified polyamide hardener that lets you load the system with fillers, push build, and still get reliable cure and bond.

This is a field-first, problem-solving guide to JH 1052 — what problems it solves, how to use it on site, practical mix guidance, and the troubleshooting tips that keep repairs permanent.

Quick technical snapshot

- Product: JH1052

- Typical phr: 40 (follow resin TDS for exact stoichiometry)

- Viscosity: 10,000–20,000 mPa·s @ 25 °C (medium–high)

- Amine value: 400–450 mg KOH/g

- Best fit: Trowel-applied repair mortars, high-filler screeds, primers where high build and mechanical strength are required.

- Packaging: Project-friendly site packs (1 / 5 / 10 / 20 kg) to simplify logistics and reduce waste.

The problem: filler-heavy mortars often fail on three fronts

- Segregation or running: Low-quality hardeners or mismatched viscosity let heavy aggregates separate, causing weak zones.

- Poor cure or incomplete crosslinking: Too much filler or wrong hardener causes under-cure, soft patches or dusting.

- Weak adhesion to substrate: Even a well-mixed mortar will fail if the primer, substrate profile or wetting is inadequate.

JH 1052 is built to reduce these failure modes by providing a viscosity profile and reactivity that’s tolerant of high filler loads while still promoting cure and adhesion.

Why JH 1052 works (practical benefits)

- Filler-tolerant viscosity: The medium–high viscosity helps hold fillers suspended — you get a consistent mortar that trowels and holds profile without excessive slump.

- Robust reactivity: Amine value in the 400–450 range gives a balanced cure even with heavy inert charge, producing good mechanical strength.

- Adhesion friendly: Designed to work with JR resin families and standard primers, promoting durable bonds to prepared concrete.

Site packs: Buying in manageable packs avoids drum-handling issues and makes precise mixing easier on small-to-medium jobs.

- How to use JH 1052 — on-site workflow

- Surface prep: Mechanically profile the concrete (shot blast or diamond grind) to the specified CSP. Remove dust, oil and surface contaminants. For very weak surfaces, prime or use a bonding slurry.

- Primer coat (optional but recommended): Seal the substrate with a diluted epoxy primer (check system TDS) to avoid entrapped air and ensure wetting.

- Choose filler & grading: Use clean, dry fillers (graded silica, quartz sand, calcined bauxite as required). Coated fillers are preferred to reduce dust and improve bonding. Target the particle size distribution recommended by your mortar spec — avoid excessive fines that increase water demand.

- Mix recipe: Follow the resin + JH 1052 phr ratio. Add fillers gradually while mixing. Use forced-action mixers for consistency. Typical filler loadings vary by system — trial mixes are essential.

- Batch control: Keep batch sizes manageable. Even though JH 1052 is not extremely reactive, large batches can generate local heat and affect workability.

- Application: Trowel or pump the mortar per system design. Compact and level; finish as specified.

- Cure & finishing: Allow early set per TDS. Mechanical trafficking times depend on ambient temp and filler load; full mechanical properties develop over days.

Troubleshooting — real fixes for common field issues

- Segregation or slurry bleed: Check filler grading and moisture content; reduce fines or increase coarse fraction. Improve mixing energy and ensure fillers are dry.

- Under-cure / soft spots: Verify mix ratio and thorough mixing. Too much filler vs resin will starve the binder — reduce filler content or increase binder proportion in future mixes.

- Poor bond to substrate: Re-check surface profile and cleanliness. Re-prime with thin coat of resin before applying mortar.

- Excessive heat in mass pours: Use smaller batches, work in cooler hours and avoid dumping warm components into warm fillers.

Safety, QA & best practice

- SDS & PPE: Nitrile gloves, eye protection and adequate ventilation are mandatory. Modified polyamides can sensitize — avoid skin contact.

- Site trials: Always perform a 1–10 kg trial with your chosen filler blend, substrate and ambient conditions. Measure pot life, work time and hardened properties.

- Record keeping: Log batch sizes, mix ratios, ambient temp and cure times for traceability and future specification tuning.

Bottom line

If your project demands high-build mortars or heavy filler screeds that stay where you place them and cure to a durable, bonded finish, JH 1052 is the pragmatic choice. It’s engineered for real-site constraints — tolerant of filler, forgiving in mixing, and available in site-friendly packs that make on-site work fast and reliable.

Leave a Reply