MR. JO JR 5857 – The Next-Generation Modified BPA Epoxy Resin for Versatile

When it comes to epoxy systems, formulators and end-users are always looking for a balance between ease of processing, mechanical strength, and long-term durability. Traditional bisphenol-A (BPA) epoxy resins offer excellent properties but often come with high viscosity, making them harder to process in certain applications.

This is where JR 5857 stands out – a modified BPA epoxy resin designed with a built-in reactive diluent to deliver low viscosity, excellent flow, and solvent-free performance.

What is JR 5857?

JR 5857 is a mono-functional reactive diluent modified BPA epoxy resin. By incorporating the reactive diluent during manufacturing, it offers a viscosity of just 600 – 900 mPa·s at 25°C, much lower than conventional resins.

- Epoxy Equivalent Weight (EEW): 196 – 204 g/eq

- Viscosity at 25°C: 600 – 900 mPa·s

- Color (Gardner): ≤ 2 (very low color, near water-clear)

- Density at 25°C: 1.05 – 1.15 g/cc

These values translate into easier mixing, excellent wetting, and smooth processing across multiple applications.

Why Modified BPA Resins Matter

Unmodified BPA resins like YD128 have excellent performance but require external diluents to reduce viscosity. This can sometimes compromise strength or long-term stability.

By contrast, JR 5857 already integrates a reactive diluent, which means:

- Lower viscosity without excessive external diluents.

- Better flow and substrate penetration.

- Consistent strength and durability.

- Reduced formulation complexity.

This makes it similar in performance to Spolchemie CHS 521, a widely known benchmark resin.

Key Applications of JR 5857

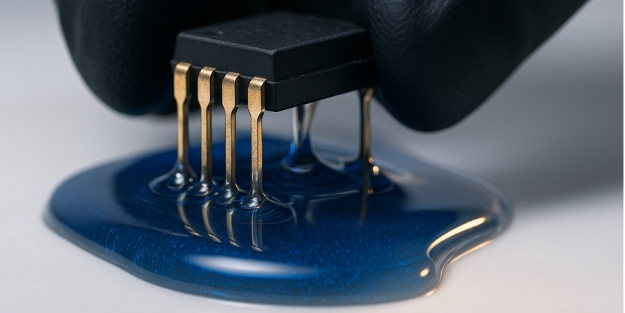

1. Potting & Encapsulation

Its very low viscosity allows JR 5857 to flow into fine gaps, making it ideal for electrical and electronic potting compounds where complete coverage and insulation are critical.

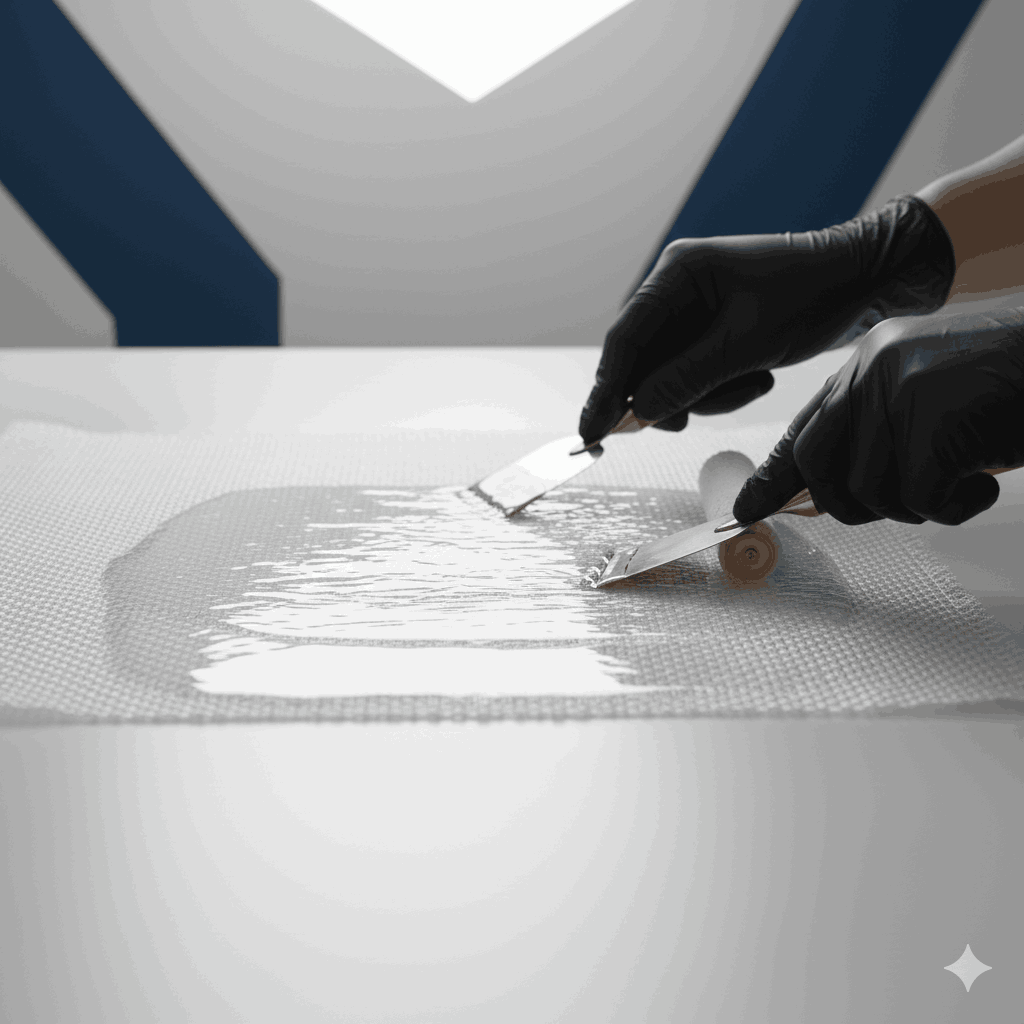

2. Industrial Coatings

With excellent flow and clarity, JR 5857 is perfect for high-performance coatings that demand smooth finishes, durability, and chemical resistance.

3. Civil Engineering Systems

For flooring, injection grouts, adhesives, and repair mortars, the resin penetrates concrete pores and cracks effectively, forming high-strength, long-lasting bonds.

Compatible Curing Agents

JR 5857 can be used with a variety of curing agents depending on the application:

- Polyamines & Polyamides – for ambient temperature curing.

- Cycloaliphatic & Aromatic Amines – for heat- and chemical-resistant systems.

- Anhydrides – for elevated temperature curing applications.

This flexibility allows formulators to tune performance to specific requirements.

Advantages of JR 5857

✔ Very low viscosity – easy processing

✔ Solvent-free – 100% solids, VOC-free

✔ Excellent substrate wetting & adhesion

✔ Clear, low color – suitable for coatings

✔ Versatile – works in potting, coatings, and civil applications

✔ Compatible with fillers, pigments, and additives

Conclusion

For formulators looking for a workhorse epoxy resin that combines low viscosity, solvent-free performance, and versatility, JR 5857 is an excellent choice.

Whether you are working in electronics potting, industrial coatings, or civil engineering systems, JR 5857 helps you achieve high performance with easier processing and reliable end results.

Leave a Reply