MR. JO Lami-HV : Versatile Epoxy System for High-Performance Lamination & Composite Fabrication

MR. JO Lami-HV : Versatile Epoxy System for High-Performance Lamination & Composite Fabrication

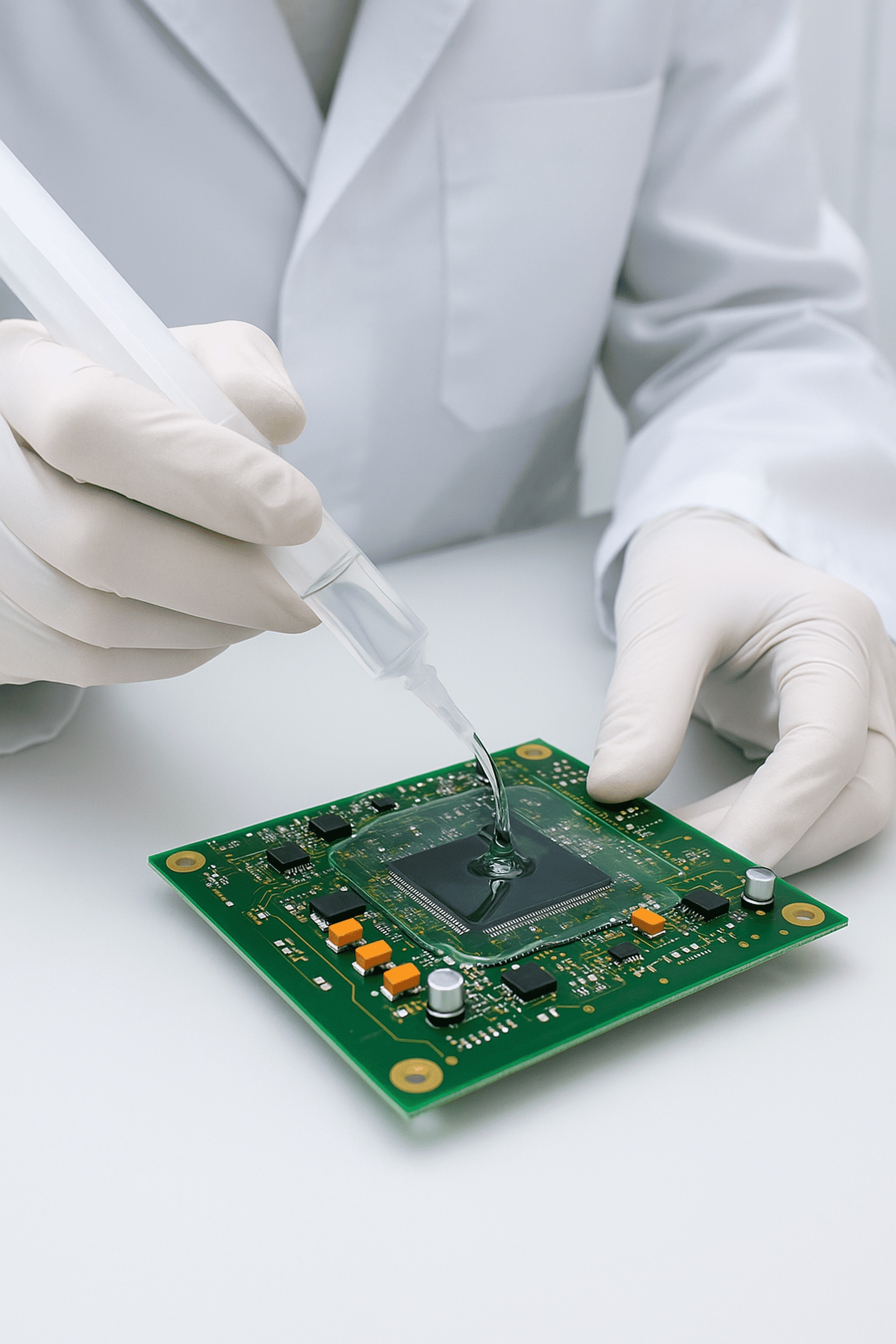

When strength, finish, and durability are non-negotiable, MR. JO Lami-HV delivers. Designed for hand lay-up lamination and tooling applications, this two-part, solvent-free epoxy resin system features medium viscosity, excellent wet-out, and superior adhesion. Whether you’re working with glass fiber, carbon fiber, or chopped strand mat (CSM), MR. JO Lami-HV flows smoothly, bonds aggressively, and cures to a tough, resilient finish.

🔍 Key Features

🧴Medium Viscosity: Offers a perfect balance of flow and control, making it ideal for hand layups.

🧲Strong Adhesion: Bonds reliably to composite reinforcements like fiberglass and carbon fiber.

💧Solvent-Free: Ensures a cleaner, safer working environment.

🔧Easy Processing: Smooth consistency allows for easy manual application.

💪Durable Finish: Cures to a hard, impact-resistant layer that resists abrasion and wear.

🌐 Multi-Industry Use: Well-suited for industrial, automotive, marine, aerospace, and composite mold making applications.

🧪 Technical Properties

| Property | Value |

| Color | Clear |

| Mixing Ratio (PBW) | 100:10 |

| Pot Life @ 25°C | 100–150 minutes |

| Mixture Consistency | Medium-viscosity liquid |

| Appearance (Cured) | Transparent |

⚙️ Applications

🛠️Glass & Carbon Fiber Laminates

Reliable wetting and strong interlaminar strength for multi-layer layups.

🧰Composite Mold & Tooling Production

Ideal for manufacturing negative molds, stencils, and laminating tools.

🚤Marine & Boat Hull Repairs

Long open time and high strength make it perfect for intricate marine applications.

🚗Automotive & Aerospace

Used in body panels, air ducts, fairings, and other precision composite parts.

🧱Electrical Insulation & Repairs

Suitable for potting, encapsulation, and repairs of insulators and electrical assemblies.

🧱 Surface Prep Recommendations

- Surface must be free from laitance, dust, oil, or loose paint

- High-pressure water blasting or wet grit blast preferred

- Optional: 15% HCl etching if other methods not feasible

- Drying not essential — can be applied on damp concrete

🎯 Why Choose MR. JO Lami-HV?

- Consistency You Can Trust

Whether you’re creating one-off prototypes or recurring production tools, MR. JO Lami-HV offers batch-to-batch consistency and excellent workability. - High Performance, No Compromise

Designed to resist mechanical and environmental stressors, the system holds up under repeated use and varied conditions. - Ideal for Vertical Surfaces

Thicker viscosity helps in maintaining resin position in hand laminations, reducing drips or runs on inclined or curved surfaces. - Professional-Grade Output

Offers glass-like finish when properly cured — ideal for parts where both appearance and performance matter.

🧼 Processing Tips

- Always mix resin and hardener in the prescribed ratio (100:10 PBW) thoroughly.

- Use a roller or brush to ensure even wetting of reinforcement fabrics.

- Degas or allow to settle before layup to reduce entrapped air.

- Apply in layers if thicker sections are required to avoid exotherm.

🔒 Storage & Safety

- Store in a cool, dry place between 18–25°C.

- Ensure containers are tightly sealed after use.

- Use PPE (gloves, goggles) during application. Refer to SDS for details.

MR. JO Lami-HV is your reliable partner for precision lamination, composite repair, and mold making — from boats to body panels, insulators to industrial tools. When you need a smooth-finish, durable epoxy with easy application and versatile performance, trust MR. JO to deliver the strength to bond and the power to protect.

Leave a Reply