MR. JO Tecbond – GS : Reliable Multipurpose Epoxy Adhesive for Industrial & Maintenance Bonding

MR. JO Tecbond – GS : Reliable Multipurpose Epoxy Adhesive for Industrial & Maintenance Bonding

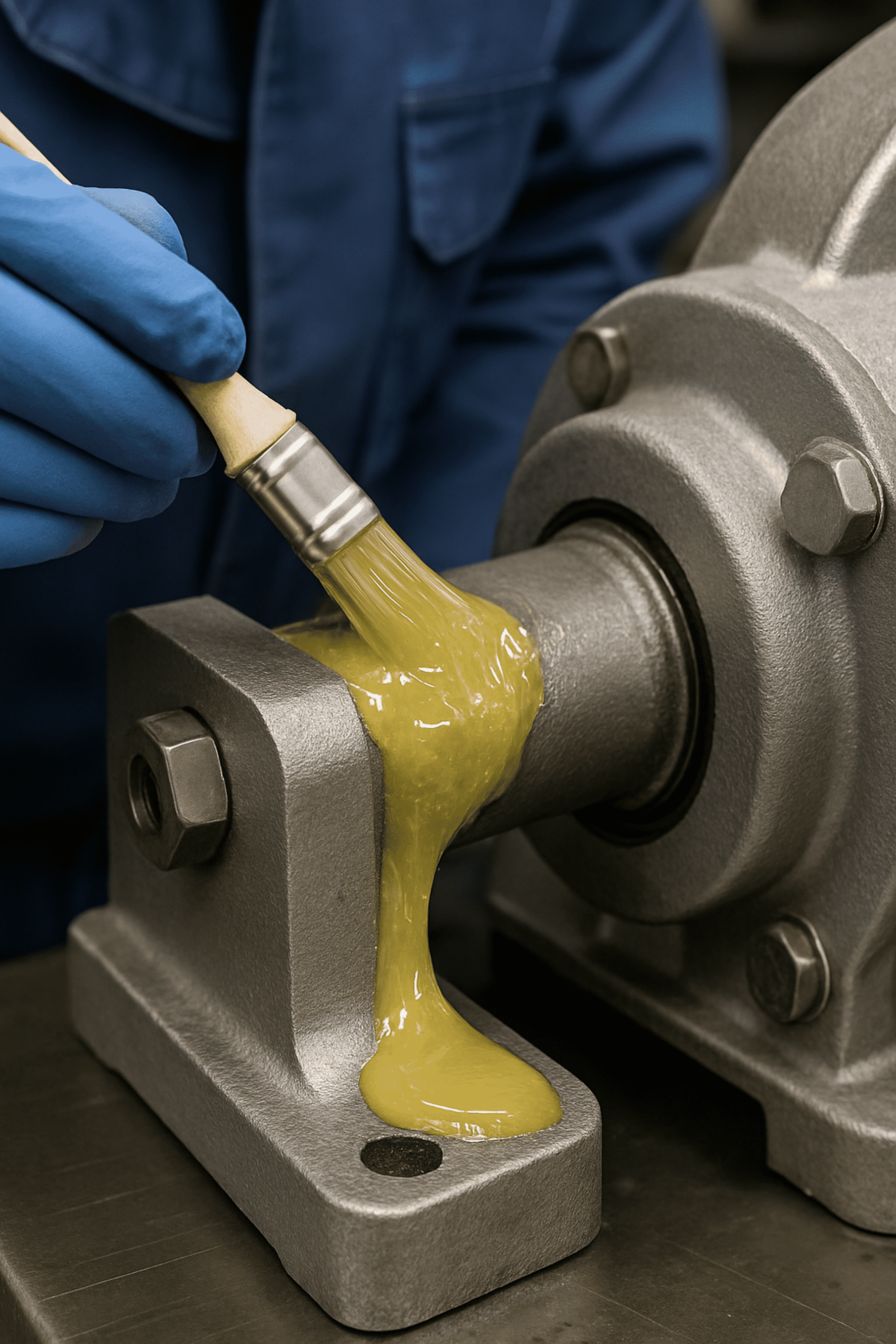

MR. JO Tecbond – GS is a versatile, medium-pot-life, solvent-free two-part epoxy adhesive developed for general-purpose bonding across industrial, construction, electrical, and maintenance sectors. With excellent adhesion to metals, plastics, wood, ceramics, and more, it is ideal for shop floor fixes, component assembly, and bonding jobs that require strength, durability, and ease of use.

Whether you’re assembling machine parts or making repairs on automotive, electrical, or consumer products, MR. JO Tecbond – GS ensures solid, reliable results.

⚙️ Product Highlights:

- Multipurpose Formulation

Designed to work across a wide range of surfaces including metal, ceramics, glass, plastics, wood, and composites. - Medium Pot Life for Balanced Work Time

Offers 60–70 minutes of workable time, perfect for controlled assembly and positioning. - High Bond Strength

The tough, non-shrinking bond holds under stress, vibration, and moderate thermal cycling. - Solvent-Free, Safe Application

No unpleasant odor or volatile organic content — safer for use in closed or indoor environments.

🧪 Technical Specifications:

| Property | Value |

| Mixing Ratio (PBW) | 100 : 80 |

| Color | Pale Yellow |

| Pot Life @25°C | 60–70 minutes |

| Mixture Consistency | Thick liquid |

| Optics | Translucent / Slightly Clear |

| Adhesive Strength* | >1 kg/sq. cm (Al to Al, Lap Joint, 25mm × 25mm) |

🔧 Recommended Applications:

- Automotive & Engineering

- Brake lining to brake shoe bonding

- Small engine part repairs

- Metal-to-metal or plastic-to-metal component assembly

- Electrical & Electronics

- Insulation bonding

- Adhesion of coil windings and plastic fixtures

- Potting small components

- Industrial Crafts & Maintenance

- Assembly of sports goods

- Ceramic or metal handicrafts

- On-site repair of tools and fixtures

🧼 Surface Preparation:

For optimum bond strength and long-lasting performance, proper surface prep is essential:

- Clean the Substrates

Remove dust, oil, grease, rust, and loose material using IPA, degreaser, or a wire brush. - Dry Surfaces Thoroughly

Surfaces must be clean and dry (damp surfaces reduce bond strength). - Roughen Smooth Surfaces

Lightly sand glossy or smooth metals and plastics to improve mechanical grip.

🧴 How to Use:

- Mixing Instructions

- Measure the resin and hardener in 100:80 PBW ratio.

- Mix slowly and thoroughly until the mixture is uniform in color and consistency. Avoid air entrapment.

2. Application

- Apply using a spatula, trowel, or dispensing syringe onto the cleaned substrate.

- Press both surfaces together evenly and hold/clamp if needed.

3. Curing Schedule

- Handling strength: ~6 hours

- Full cure: ~24–48 hours at room temperature

- Optional heat post-cure (40–50°C) for enhanced strength

⚠️ Handling & Safety Tips:

- Do not mix large quantities at once to avoid premature gelling due to exothermic reaction.

- Use gloves and work in a ventilated space.

- Clean tools immediately after use with IPA or epoxy thinner.

- Shelf life: 12 months when stored in sealed container at cool, dry conditions.

✅ Why Choose MR. JO Tecbond – GS?

✔ Perfect blend of workability, strength, and versatility

✔ Easy-to-use system with moderate curing time

✔ Trusted by manufacturers and maintenance teams across multiple sectors

✔ Fully compatible with MR. JO Tecbond accessories and systems

Leave a Reply