MR. JO Tecbond Series – The Backbone of Brush Bonding

In the world of paint brush manufacturing, quality isn’t judged by looks alone — it’s tested in every stroke, every rinse, every coat applied. What makes a brush professional-grade is not just the bristle or the handle — but the bond that holds it all together.

🎯 Designed for a Singular Purpose: Locking the Bristles. Perfectly. Permanently.

The LV family of epoxy adhesives is engineered specifically to bond brush hair (synthetic or natural) securely into the metal ferrule or plastic sockets of a paintbrush. Once cured, the epoxy resists solvents, heat, moisture, and ensures no hair fall — even after hundreds of uses.

🧪 The Range at a Glance

| Product | Mixing Ratio | Key Traits | Ideal For |

| LVI | 100:10 | Premium, lower viscosity, smooth curing | Precision bonding, less filler |

| BLV | 100:10 | Economical version of LV | Budget-conscious applications |

| LVT | 100:10 | New-age, cost-effective, well-balanced system | Value-oriented producers |

| LV50 | 100:50 | 50% solid, easy-to-mix, automation-ready | Semi/fully automated lines |

⚙️ Built for Manufacturers, Not Just Users

Brush manufacturers face these daily challenges:

- Hair fallout after curing due to weak bonding

- Messy mixes and ratio errors in manual blending

- Slow curing and long turnaround times

- Incompatibility with automated dispensers

Each formulation was developed with real plant feedback, solving one or more of these problems.

🧱 Surface Prep Recommendations

- Surface must be free from laitance, dust, oil, or loose paint

- High-pressure water blasting or wet grit blast preferred

- Optional: 15% HCl etching if other methods not feasible

- Drying not essential — can be applied on damp concrete

🛠️ The Manufacturing Process – Where LV Makes a Difference

- Bristle Setting

- The selected bristles are arranged inside the ferrule or socket.

- Epoxy Preparation

- LV system is mixed by weight (see ratio) and optionally filled with silica or stone powder to control flow.

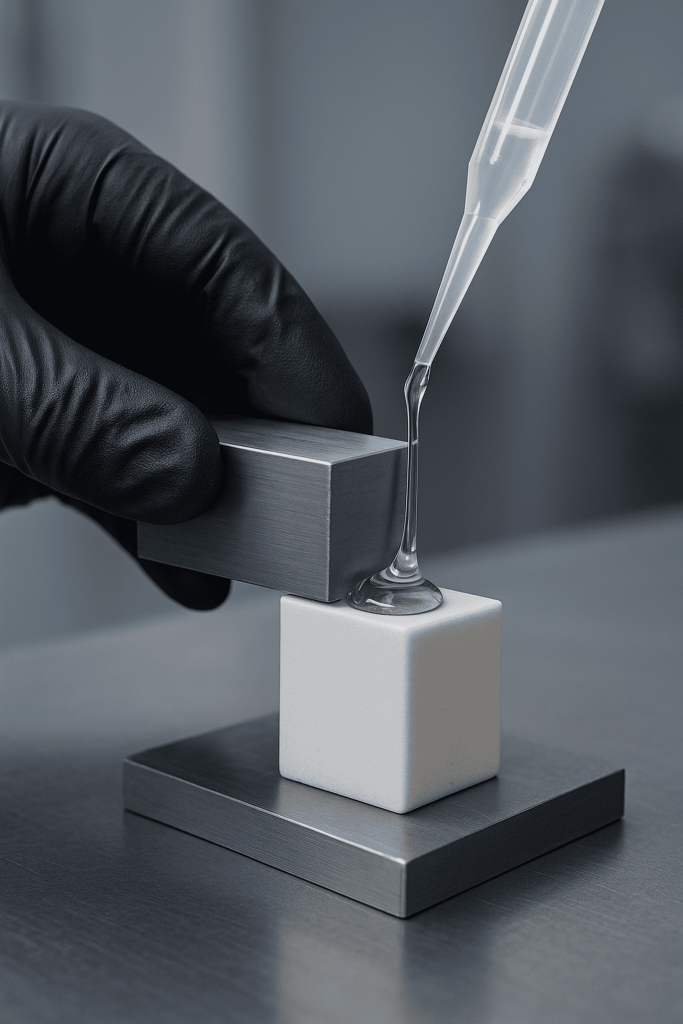

- Dispensing & Fixing

- Epoxy is poured or injected into the bristle root zone. Low to medium viscosity ensures flow without runout.

- Curing

- Can be cured at room temperature (24–48 hrs) or oven-cured at 60°C (2–3 hrs) to accelerate production.

- Handle Assembly

Once the epoxy sets, handles are attached and brushes move to finishing and packaging.

🧩 LV50 – The Star of Automation

Modern brush lines are leaning towards automated mixing and dispensing, where maintaining a 100:10 ratio is cumbersome. LV50 solves this by offering a 100:50 ratio, enabling:

- Fewer errors

- Easier batch mixing

- Machine-friendly proportions

🧠 Choosing the Right LV for Your Needs

| Need | Recommended Product |

| Faster, cleaner, premium handling | LVI |

| Budget solution, low cost | BLV |

| Modern value-focused option | LVT |

| Automation and easy mixing | LV50 |

✅ Why Leading Brush Manufacturers Trust MR. JO Tecbond Series

🧷Zero Hair Fall Guarantee

🧪Solvent & Water Resistance

🧰Compatible with Fillers

🧠Simplified Ratios

🔄Cure Flexibility – Room or Oven

🏭Proven Across Small and Large Plants

Leave a Reply