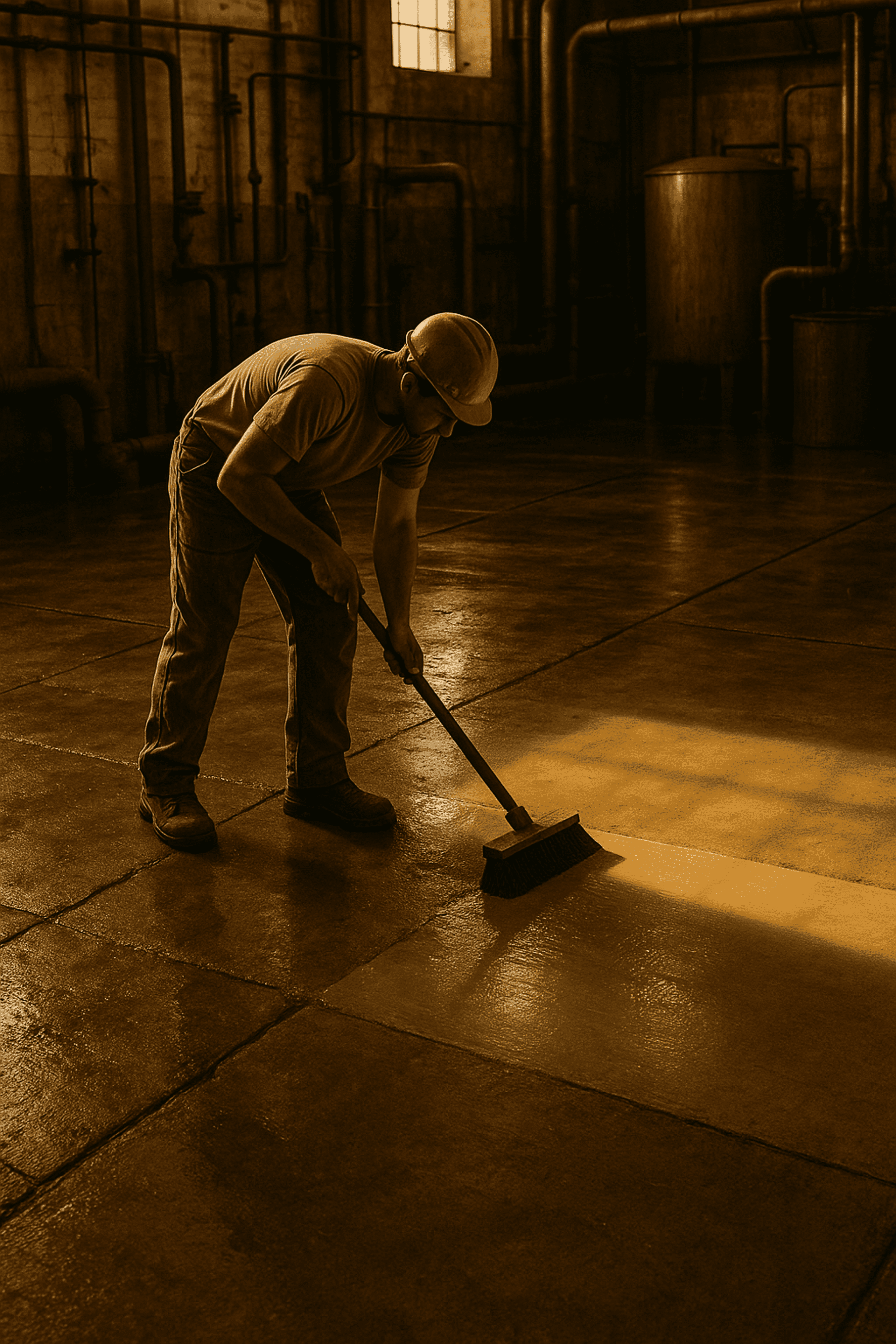

Stop Corrosion Before It Starts: Why MR. JO ProtectoKot-CR Is the Industry’s Go-To Barrier Coat

From effluent drains to factory floors, coastal machinery to chemical tanks — corrosion is not just ugly, it’s expensive, dangerous, and inevitable without the right protection.

And yet, many coatings fail due to improper prep, poor formulation, or short-lived adhesion.

MR. JO ProtectoKot – CR is here to change that — a solvent-free, high-performance epoxy coating trusted across industries for long-term protection of metal and concrete structures against corrosion and chemicals.

🧩 The Problem

Corrosion isn’t just about rust. In industrial settings, it means:

- Equipment failures

- Downtime losses

- Structural degradation

- Unsafe work conditions

Chemical processing zones, textile units, food and beverage plants, and even water treatment systems — all face aggressive exposure from moisture, solvents, and acidic fumes.

🧪 Concrete begins to dust.

⚠️ Steel starts to pit.

🚫 Standard paints peel and perish.

What’s needed is a proven epoxy system that holds up even when solvents, sulphuric acid, and saltwater don’t play fair.

🧪 The Solution: MR. JO ProtectoKot – CR

MR. JO ProtectoKot-CR is a solvent-free epoxy system that forms a dense, chemical-resistant film over sandblasted steel or etched concrete, offering:

- Long-term anti-corrosion protection

- Excellent solvent and acid resistance

- Strong adhesion to properly prepared surfaces

- Compatibility with quartz-filled screeds

With decades of field usage, MR. JO ProtectoKot-CR is a versatile workhorse in environments where safety, cleanliness, and corrosion resistance matter most.

⚙️ How It’s Used

✅ Compatible Surfaces:

- Mild steel & ferrous metals

- Concrete floors, tanks, bunds

✅ Surface Preparation:

- Metal: Sandblasting or grit blasting for rust removal. Follow with degreasing using trichloroethylene or hot air.

- Concrete: Sandblasting or mechanical abrading. If not feasible, acid etching using 15% HCl followed by water wash and drying.

🎯 Good adhesion = clean, rough, dry surface.

✅ Application:

- Mix ratio: 100:60 PBW

- Application: Brush or roller

- Primer:

- MR. JO Primer-MVC/LVC for dry surfaces

- Mr. JO Primer UPS for moist/under-prepared areas

✅ Coverage & Build:

- ~130–150 microns per coat

- Coverage: 4–5 m²/kg

- Typically 2–3 coats

- Touch dry in 4–6 hrs @ 25°C

Final cure: 7 days for full chemical resistance

🔍 Use Case Snapshot

🧱 Substrate: Sandblasted mild steel

🧪Environment: Fertilizer plant near coastal zone

🎯Film Thickness: 400 microns

🧭Results After 12 Months:

- Sulphuric acid 30% – ✔ Resistant

- HCl 20% – ✔ Resistant

- Solvents (Toluene, Benzene, Xylene) – ✔ Resistant

- Lactic, Acetic, Caustic Soda – ✔ Resistant

- Sea water, crude oil – ✔ Resistant

💬 “After a year, the steel showed zero signs of underfilm rust. Easy to mix, apply, and inspect. This has become our standard.”

— Maintenance Engineer, Chemical Manufacturing Unit

🔗 Additional Advantages

🔹 Can be Screeded:

Mix with quartz sand to form a high-strength screed for:

- Drains

- Chemical bunds

- Containment zones

🔹 VOC-Free, Indoor Safe:

- No harsh solvent odors

- Low shrinkage

- Eco-compatible for indoor industrial use

🔹 Long-Term Adhesion:

- Excellent intercoat adhesion

- No peeling or cracking under thermal cycling

🏭 Who’s Using MR. JO ProtectoKot-CR? - Fertilizer and Chemical Plants

- Textile and Paper Mills

- Sugar, Beverage, and Fats Processing Units

- Ships, Pipes, STPs, and Effluent Systems

- refineries and Coastal Installations

💡 Why It Outperforms Alternatives

| Feature | PU | Polyester | MR. JO ProtectoKot-CR |

| Solvent-Free | ❌ | ❌ | ✅ |

| Chemical Resistance | Moderate | Good | ✅ Excellent |

| Water Resistance | Good | Moderate | ✅ Excellent |

| Thickness Build | Low | Medium | ✅ Customizable |

| VOC & Odor | High | High | ✅ Low/None |

| Recoatable | Limited | Limited | ✅ Excellent |

🧪 Summary – A Workhorse That Doesn’t Quit

MR. JO ProtectoKot-CR is not just a coating, it’s a barrier technology — one that’s proven across hundreds of installations for:

- Corrosion resistance

- Chemical resilience

- Screed convertibility

- Wide surface compatibility

Whether you’re protecting concrete tanks or restoring metal pipelines, this is the coating to start with.

Leave a Reply