Which MR. JO hardener should you pick? — A compact selector guide for the blog page

Which MR. JO hardener should you pick? — A compact selector guide for the blog page

Imagine Ravi, a site supervisor juggling a glossy commercial floor, a damp repair corner, and a client who wants the production line back tomorrow. He doesn’t need a chemistry lecture — he needs a fast, confident decision. That’s exactly what this selector does: a practical, tech-smart guide that points you to the right modified / speciality hardener based on what the job actually demands. All grades below are available in project-friendly packs (1 / 5 / 10 / 20 kg typical), so you order only what you need and get straight to work.

Quick at-a-glance selector (scan & choose)

| Product | phr (typical) | Viscosity (mPa·s @25°C) | Amine value (mg KOH/g) | Best fit |

| JH 1001 | 50 | 100–500 | 250–300 | Flooring — high gloss, blush resistant (hot/humid) |

| JH 1010 | 50 | 200–600 | 300–400 | Fast / cold-region accelerator for JH1001 |

| JH 1030 | 60 | 700–900 | 260–280 | Chemical-resistant aromatic — industrial floors, tanks |

| JH 1039 | 20 | 3,000–5,000 | 730–840 | Extreme chemical resistance, high hardness (short pot life) |

| JH 1055 | 40 | 350–750 | 410–490 | Low-visc primer / injection grouting (fast) |

| JH 1052 | 40 | 10,000–20,000 | 400–450 | Medium/high viscosity — filler-friendly repair mortars |

| JH 1050 | 60 | 900–1,800 | 250–300 | Adhesion promoter for poorly prepared substrates |

| JH 1053 | 40 | 1,200–1,600 | 320–400 | Moisture-tolerant — cures in wet/submerged conditions |

| JH 1059 | 18 | 100–250 | 650–750 | Very fast set — emergency grouts, rapid repairs |

| JH 1057 | 50 | 500–1,000 | 420–455 | Low-colour, water-wipeable — tile grouts |

| JH 8357 | 45 | 150–350 | 450–500 | Ultra-clear, bubble-friendly topcoats & decorative floors |

| JH 8347A | 60 | 350–500 | 260–290 | Low yellowing cycloaliphatic — clear coats with chemical resistance |

| JH 1040 | 100 | 1,250–1,500 | 100–150 | Coal-tar polyamine — marine / saltwater protection, legacy specs |

How to use this guide — pick by problem, not by jargon

- Need a glossy, durable floor in hot/humid sites?

Start at JH 1001. If the job is cold or you need faster turn-around, blend in JH 1010 (accelerator). - Working on repairs, mortars or high-filler screeds?

Use JH 1052 (holds fillers, great for trowel work). Prime with JH 1055 if you need fast wetting and early strength. - Substrate is damp, wet or submerged?

Go straight to JH 1053 — specifically engineered to cure in the presence of moisture. - You need chemical resistance (fuels, solvents, acids)?

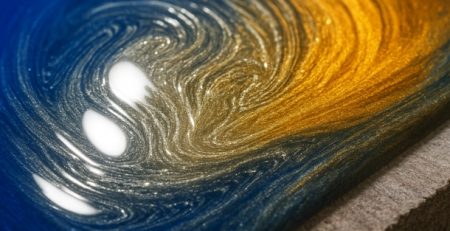

JH 1030 is the robust aromatic choice; JH 1039 gives the highest chemical resistance and hardness (expect a short working window). - Decorative, crystal-clear topcoats or art-grade floors?

JH 8357 for ultra-clear, low-colour finishes; choose JH 8347A where low yellowing and added chemical resistance matter. - Emergency grouting / rapid return to service?

JH 1059 is formulated for very fast set and early load bearing.

On-site rules of thumb (fast)

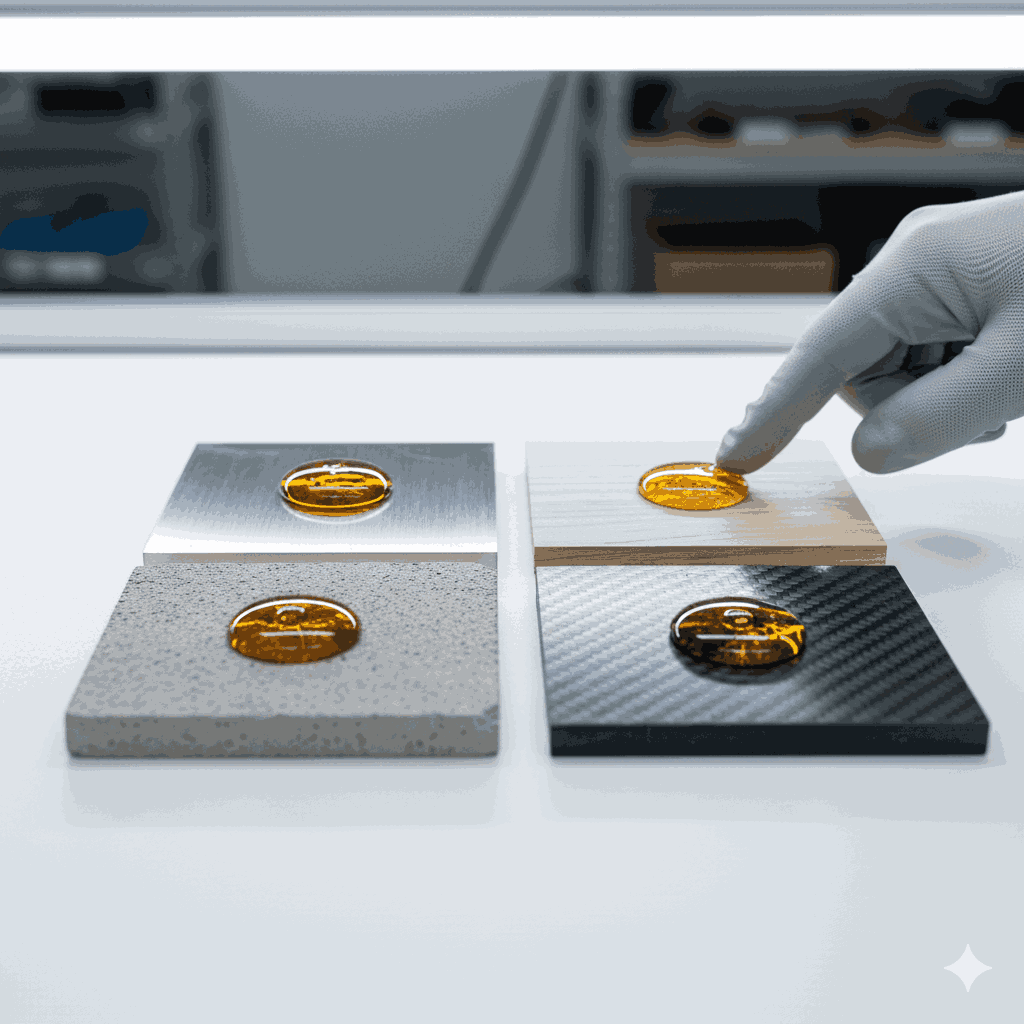

- Low viscosity (<1,000 mPa·s) → better penetration and bubble release (clear coats, primers).

- High viscosity (>1,000 mPa·s) → holds fillers, ideal for mortars and screeds.

- Higher phr generally means more hardener by weight — follow the TDS for optimal stoichiometry.

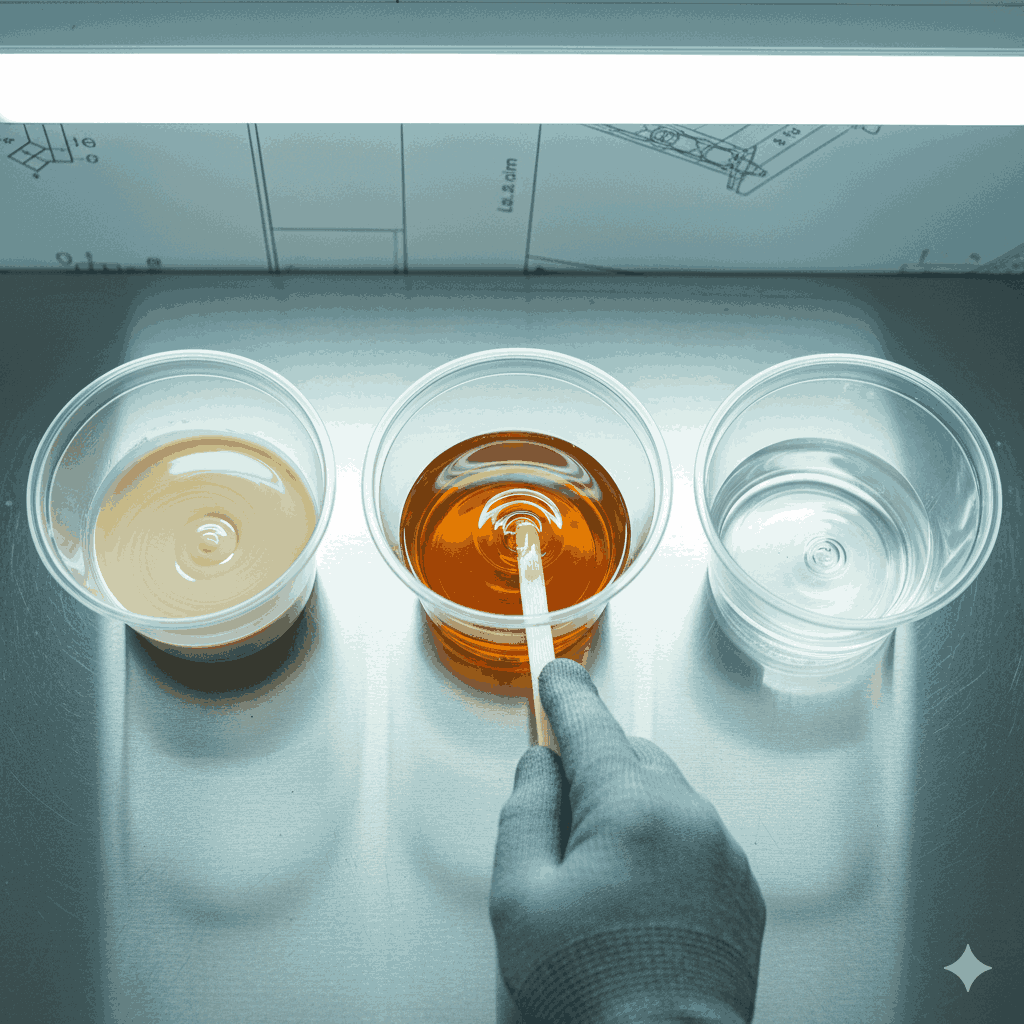

- Always do a 1–5 kg site trial with your chosen resin + hardener + pigments/fillers to validate pot life, colour and exotherm.

Why MR. JO’s site packs matter

Buying small, project-sized packs avoids waste, simplifies handling and reduces dosing errors. For applicators like Ravi, that means fewer delays, fewer callbacks, and predictable results every time.

Leave a Reply