MR. JO Tecbond – UP : Premium Multipurpose Epoxy Adhesive for Structural Bonding

MR. JO Tecbond – UP : Premium Multipurpose Epoxy Adhesive for Structural Bonding

MR. JO Tecbond – UP is a high-strength, solvent-free, unfilled two-part epoxy adhesive developed for demanding structural applications in civil, mechanical, and electrical industries. With its medium viscosity, long pot life, and superior bonding performance, it is ideal for general-purpose and heavy-duty use — especially where reliability, ease of use, and high mechanical strength are required.

Whether you’re anchoring rebars, bonding dissimilar substrates, or repairing machinery components, MR. JO Tecbond – UP delivers robust, permanent adhesion with confidence.

⚙️ Product Highlights:

- Strong Structural Bonding

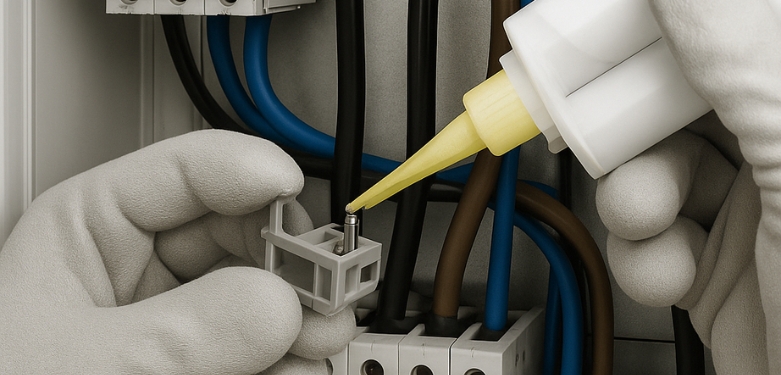

Bonds securely to a wide variety of substrates including concrete, metal, ceramics, plastics, wood, and composites. - Medium Flow for Easy Application

The controlled medium viscosity allows for easy spread without sagging, suitable for horizontal and vertical applications. - Extended Working Time

With a pot life of 80–100 minutes, it offers ample time for precise alignment and positioning. - Excellent Mechanical Strength

Tested to deliver adhesive strengths exceeding 1 kg/sq. cm under lap shear (Al–Al joints), making it ideal for high-stress assemblies.

🧪 Technical Specifications:

| Property | Value |

| Mixing Ratio (PBW) | 100 : 80 |

| Color | Pale Yellow (Other colors available on request) |

| Pot Life @25°C | 80–100 minutes |

| Mixture Consistency | Medium viscous, flowable liquid |

| Optics | Translucent / Opaque |

| Adhesive Strength | >1 kg/sq. cm (Lap Joint – Al to Al, 25x25mm) |

🛠️ Recommended Applications:

- Construction & Infrastructure

- Rebar anchoring in RCC slabs

- Bolt embedding

- Stone-to-metal or wood-to-concrete interfaces

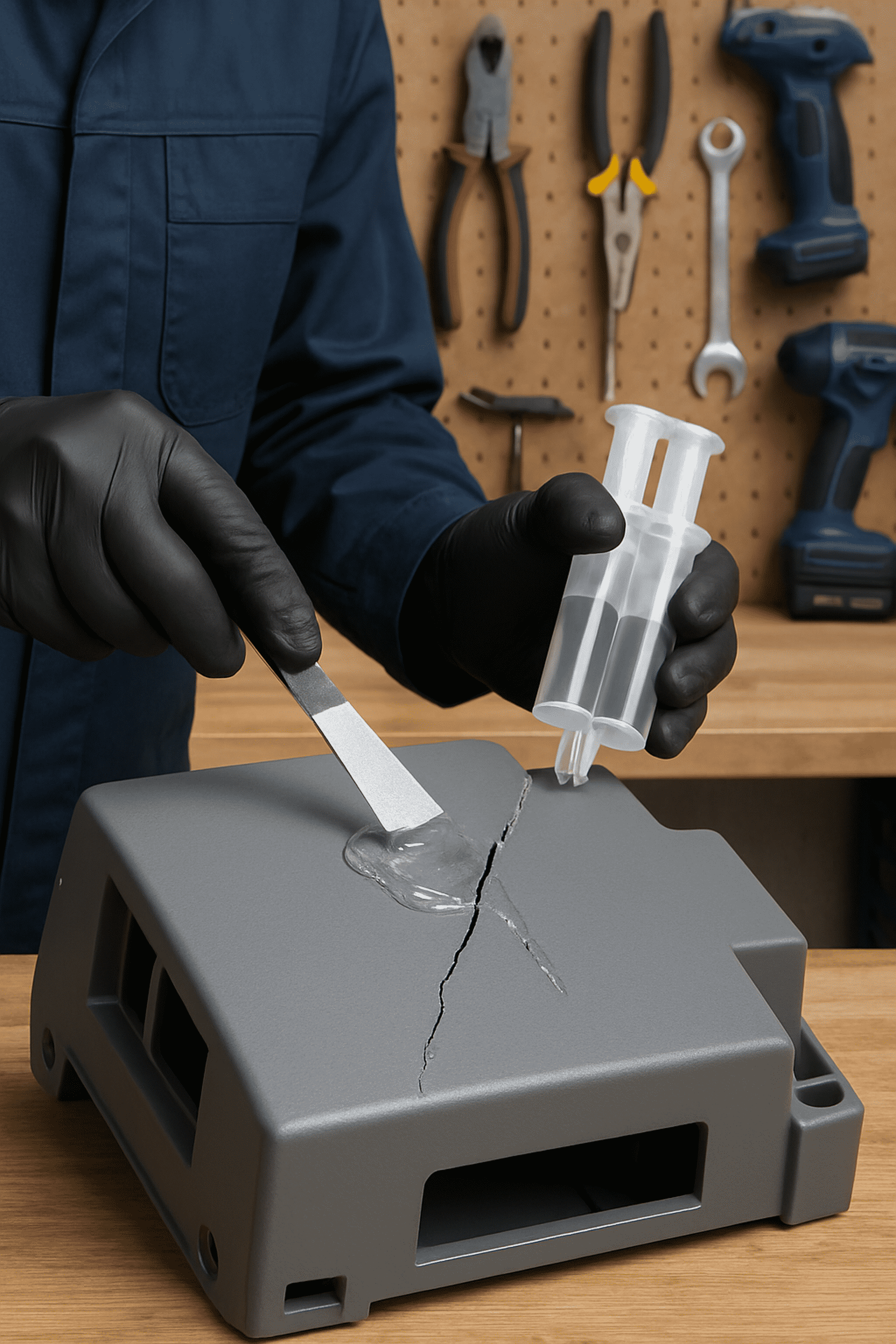

- Repairs & Retrofitting

- Filling voids and cracks in machinery bases

- Heavy-duty part bonding in manufacturing facilities

- Repairing chipped stone, ceramic, or damaged plastic components

- Multi-Substrate Adhesion

- Composite materials to metals

- Plastics to ceramics

- Wood-to-metal or stone

🧼 Surface Preparation:

Proper surface preparation is essential for best results. Follow these steps:

- Clean the Surface Thoroughly:

Remove all dust, grease, loose particles, oils, and rust using a wire brush, degreaser, or suitable solvent. - Dry the Surface:

Ensure the substrate is dry and free from standing water. Slightly damp concrete may be acceptable but avoid visibly wet or oily surfaces. - Roughen Smooth Surfaces:

On smooth metals or plastics, lightly abrade or sand the surface to enhance mechanical grip. - Trial Fit:

Before mixing, dry-fit the components to ensure proper alignment and positioning during bonding.

🧴 How to Use:

- Mixing:

- Mix resin and hardener in 100:80 PBW ratio thoroughly until a uniform, streak-free blend is achieved.

- Use a clean, dry spatula or mixing blade. Avoid whipping air into the mix.

- Application:

- Apply the adhesive on both bonding surfaces using a spatula, notched trowel, or brush.

- Press the surfaces together firmly. Use clamps if needed.

- Curing:

- Initial handling strength: 6–8 hours

- Full cure: 24–48 hours (depending on temperature and layer thickness)

- Post-Cure Options:

In critical applications, mild heating (~40–50°C) can accelerate curing and increase final properties.

⚠️ Precautions & Storage:

- Mix only as much material as can be used within the pot life.

- Use gloves and eye protection. Avoid skin contact.

- Clean tools with IPA or epoxy thinner immediately after use.

- Store in a cool, dry place. Shelf life: 12 months in sealed container.

✅ Why Choose MR. JO Tecbond – UP?

- ✔ Trusted alternative to global standards like Araldite® AW106/HY953

- ✔ Superior strength for industrial, civil, and maintenance work

- ✔ Available in multiple pack sizes for workshop, site, or retail sale

- ✔ Part of MR. JO’s Tecbond Series — engineered for lasting bonds

Leave a Reply