How to Fill Cracks in Marble and Natural Stone Slabs — A Reliable Epoxy Solution

Location: Kishangarh, Udaipur, Makrana

Application: Ongoing in marble processing units across India

🧩 The Problem: Hidden Cracks, Visible Losses

Marble slabs, especially white and light-colored varieties, often develop fine surface cracks and micro-defects during extraction, handling, or storage. These defects may seem minor, but they lead to breakage during polishing, reduce usable area, and result in significant material loss and customer rejection. In high-throughput processing units, there’s also the need for a room-temperature curing solution that ensures quick turnaround without the need for ovens or heat guns.

🧑🔧 The User: Skilled, Hands-On Craftsmen in the Field

The product is widely used by marble processors and technicians who manually inspect, mix, and apply crack fillers across large batches of slabs.

These users:

- Have experience with epoxy weighing and mixing

- Understand pot life management

- Are able to blend marble powder into the epoxy system for color matching when needed

They require a product that is easy to handle, consistent in quality, and gives them confidence in the final appearance of high-value marble.

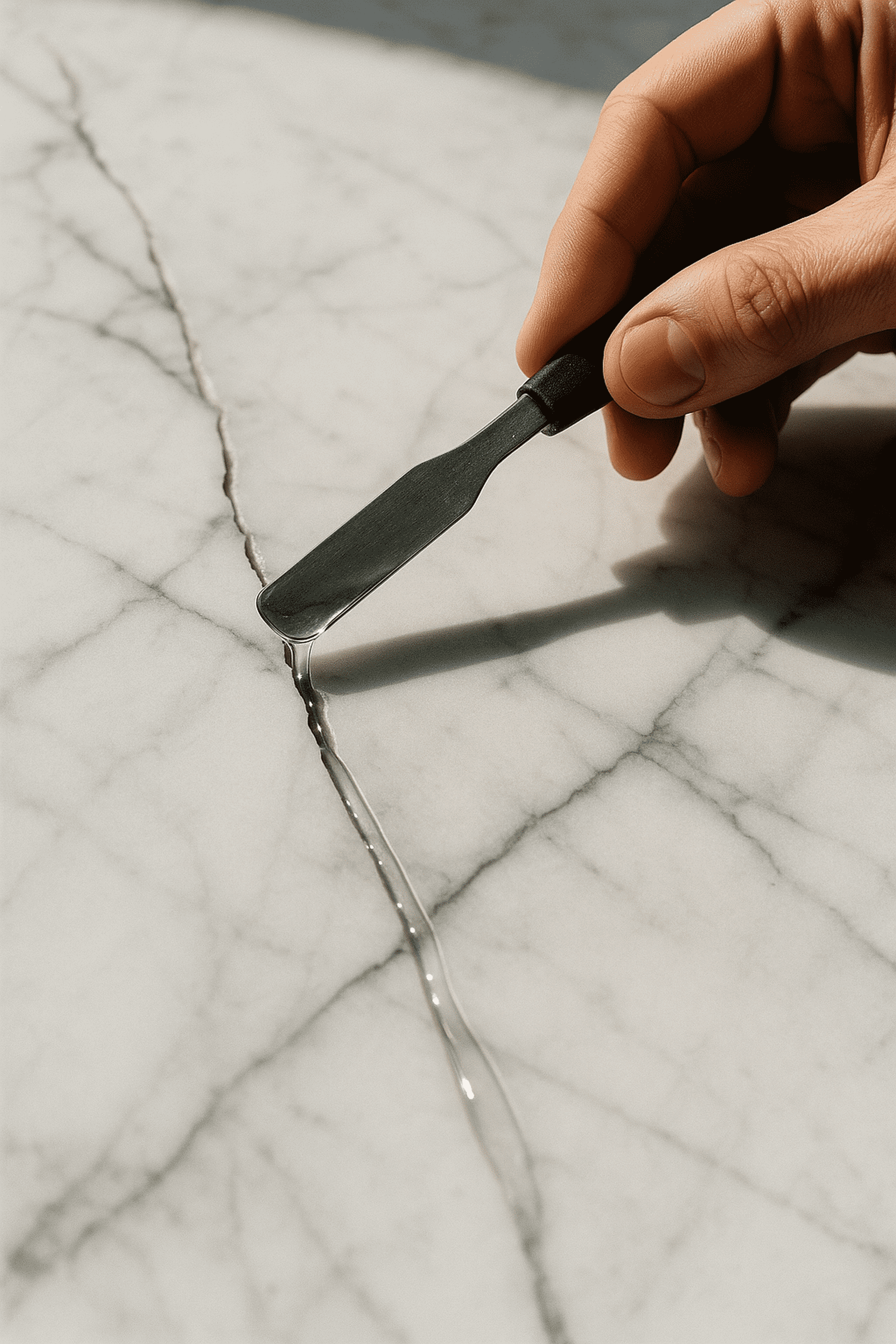

🛠️ The Application: A Simple Yet Effective Process

Product Used: MR. JO Marblefill – a solvent-free, ultra-clear, very low viscosity epoxy

Surface: White marble and natural stone slabs

Step-by-Step Application:

- The slab surface is cleaned and dried.

- Resin and hardener are weighed in a 100:10 PBW ratio and mixed thoroughly.

- The mixture is transferred into a plastic squeeze bottle with a nozzle.

- The epoxy is dispensed directly into the visible and hairline cracks.

- Material is allowed to cure overnight at room temperature.

Note: The product is used in small batches (100–200g) to avoid wastage and maximize working time.

📈 The Result: No Refills, No Breakage, Faster Processing

Once applied and cured, MR. JO Marblefill fills cracks invisibly, does not shrink or settle below the stone surface, and can be polished the next day without any issues. This eliminates the need for repeat filling or rework.

Key Benefits Noted:

- Room temperature cure — no special equipment required

- High clarity and bonding — final film is equal to wet finish

- No solvent shrinkage — no second filling needed

- Quick slab turnaround — material ready for polishing next day

- Excellent wetting and flow — reaches even microcracks

User feedback:

“Easy to use, reliable quality, strong adhesion, and a smooth finish. It doesn’t sink or fade after curing, which saves time and effort.

🧪 Technical Superiority

Compared to traditional polyester-based fillers or cheaper epoxies:

- MR. JO Marblefill has better flow characteristics

- It gives a clearer, more natural finish

- It avoids yellowing and surface dullness over time

- Being solvent-free, it is safer for operators and the environment

🔗 Related Product: MR. JO Marblewrap – For Pre-Cut Block Sealing

In many processing units, MR. JO Marblewrap is used before cutting marble blocks into slabs. This wrap forms a protective epoxy film around the block, preventing edge and corner breakage during cutting.

Together, Marblewrap + Marblefill form a powerful system:

- Marblewrap seals the block → Marblefill repairs the slab

Ensures minimum waste and maximum polish yield

✅ Conclusion

If you’re working with high-value marble and natural stone, MR. JO Marblefill is a workshop-friendly, field-tested solution that delivers on clarity, strength, and speed. Whether you’re a fabricator in Makrana or an exporter in Udaipur, this system helps you save slabs, reduce waste, and maintain finish quality — without changing your current process.

Leave a Reply