Cladding Adhesives Decoded: Why MR. JO Tecbond-X Solves the Problems Others Can’t

The Problem with Cladding Adhesives Today

Architects, contractors, and homeowners face a recurring nightmare with external and internal cladding jobs:

- Debonding after a few seasons of rain & heat.

- Hollowness in the bond line leading to “drummy sounds.”

- Stains and seepage due to moisture ingress from behind the cladding.

- Compatibility issues – some adhesives don’t bond well with granite, marble, glass, or metal.

- Safety risks when large panels loosen over time.

The question is simple: Can one adhesive really solve all these problems?

🚧 Why Floor Marking Matters More Than Ever

Factories, warehouses, cleanrooms, and even large retail units today rely on color-coded floor layouts to:

- Separate work zones from walkways

- Highlight hazardous areas (chemical storage, forklift paths)

- Mark equipment zones

- Guide people through clean and efficient movement

- Comply with 5S, OSHA, or factory audit standards

But conventional floor tapes peel off, fade, or collect dirt. And low-cost paints? They chip, smudge, and often need monthly retouching.

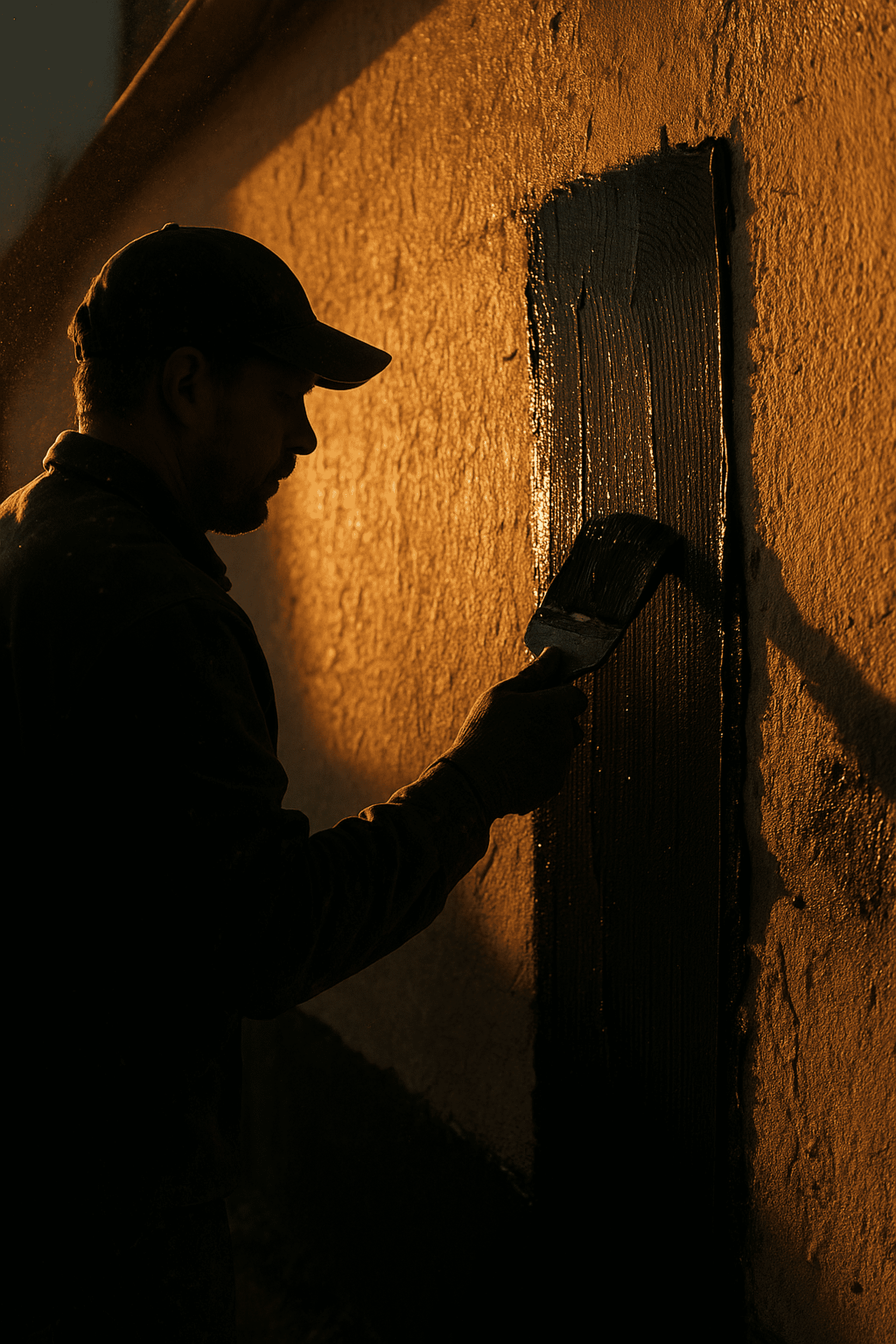

Introducing MR. JO Tecbond-X – Our Favourite Cladding Adhesive

MR. JO Tecbond-X isn’t just another adhesive; it’s engineered to take on the harshest challenges of cladding jobs.

✔️ Epoxy-based system – bonds strongly with granite, marble, metal, composites, and ceramics.

✔️Moisture-proof bond – prevents seepage-related failures.

✔️Non-shrink formulation – no hollow patches or bond line collapse.

✔️High mechanical strength – panels stay fixed even under load and weather stress.

✔️Universal substrate compatibility – works with concrete, stone, metal, ACP, and more.

It gives applicators peace of mind: once fixed, it stays fixed.

Comparative Angle: Why Tecbond-X Wins Over Conventional Adhesives

| Feature | Cementitious Adhesives | PU / Silicone Sealants | MR. JO Tecbond-X |

| Bond Strength | Moderate, weakens with moisture | Flexible but not structural | Very high, structural grade |

| Moisture Resistance | Poor (absorbs water) | Good, but can yellow/age | Excellent, non-porous |

| Substrate Compatibility | Limited (needs porous surface) | Works only on selected surfaces | Universal (stone, metal, ACP, ceramic, glass) |

| Durability in Weather | Cracks & loses adhesion | Can peel under UV/aging | Long-lasting, weather-resistant |

| Safety for Heavy Panels | Risky | Not recommended | Ideal – engineered for cladding loads |

| Finish | Uneven, prone to seepage marks | Can ooze, messy | Clean, controlled bond line |

Where Does Tecbond-X Fit Best?

- High-rise façades with granite/marble panels

- Luxury interiors where staining is unacceptable

- ACP and glass façades needing structural reliability

- Retrofit projects where older adhesives failed

Conclusion – Stop Repairing, Start Fixing Right

Most cladding failures happen not because of the stone or panel, but because of the wrong adhesive. By switching to MR. JO Tecbond-X, you solve problems before they occur – stronger bonds, zero seepage, higher safety, and peace of mind.

Leave a Reply