MR. JO Electrokot-HB: Solving the Hidden Challenges of Electrical Insulation

When we talk about induction furnaces or high-performance electrical equipment, most people think of power, precision, and productivity. But beneath the surface, there’s a quiet, constant battle being fought: protecting coils and components from electrical stress, overheating, and breakdowns.

And this is where the right insulation coating makes all the difference.

The Problem: When Insulation Fails, Everything Fails

Induction furnace coils work under extreme conditions—high currents, fluctuating temperatures, continuous heating and cooling cycles. Without robust insulation:

- Arcing or short-circuits can occur, halting production instantly.

- Moisture ingress can creep in, especially in humid environments, weakening insulation layers.

- Overheating leads to coating cracks and premature failure.

- Frequent maintenance adds downtime and costs, eating into efficiency.

Operators often try quick fixes—tapes, low-quality varnishes, or thin coatings—that don’t last. The result? A cycle of patchwork repairs and rising maintenance bills.

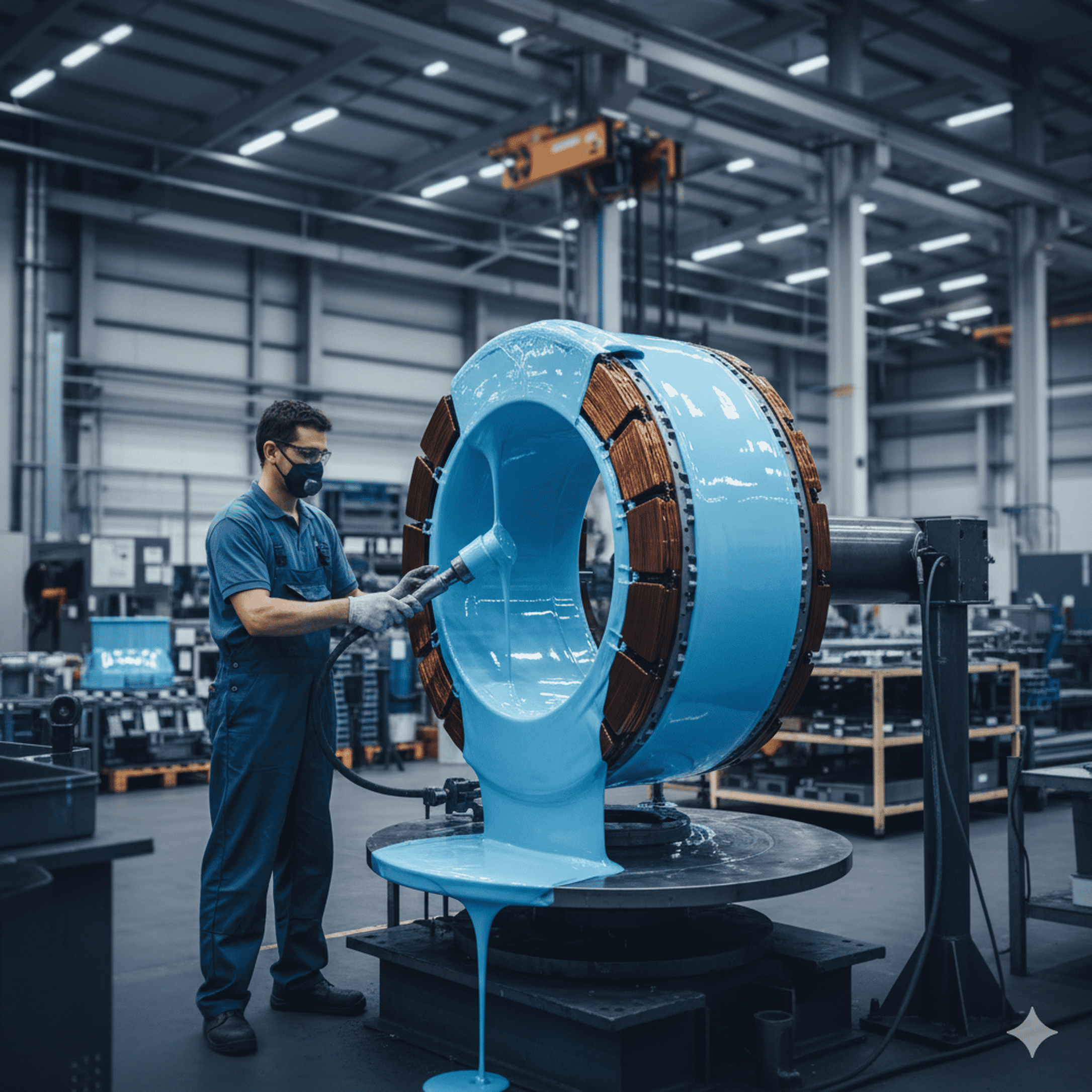

The Solution: MR. JO Electrokot-HB

MR. JO Electrokot-HB was developed with these exact challenges in mind. It isn’t just a coating; it’s a shield for electrical components.

Here’s how it solves the problems:

✅ High Insulation Strength

Each coat (100–150 microns) builds a strong dielectric barrier. With 2 coats, you achieve insulation of 10–12 kV, offering reliable protection even under high-voltage stress.

✅ Durable Film

Unlike thin varnishes that peel or crack, Electrokot-HB forms a hard, consistent film that resists thermal stress and maintains adhesion on copper coils and other substrates.

✅ Moisture & Heat Resistance

It safeguards against moisture ingress and thermal degradation, extending coil life in harsh operating conditions.

✅ Ease of Application

Brush, roller, or spray—Electrokot-HB is formulated for shop-floor practicality. Each coat dries quickly, allowing faster turnaround and less downtime.

Real-World Impact

Imagine this scenario:

An induction furnace operator struggles with frequent coil breakdowns. Every 2–3 months, production halts for rewinding and re-insulation, costing lakhs in downtime. After switching to MR. JO Electrokot-HB, insulation life doubles—sometimes triples. Instead of firefighting breakdowns, the operator can now plan maintenance cycles confidently, improving both uptime and profitability.

That’s not just a coating. That’s peace of mind.

When Should You Choose Electrokot-HB?

- If you’re repairing or recoating induction furnace coils.

- If you need thicker, reliable insulation per coat.

- If moisture or heat-induced failures are recurring.

- If you want to reduce maintenance costs by extending coil life.

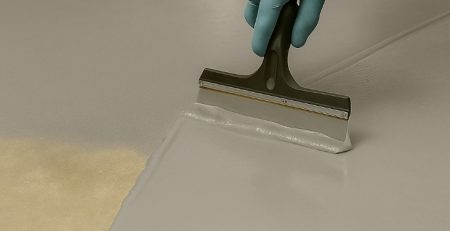

How to Use It Effectively

- Prepare the surface – clean and dry, free from oil and dust.

- Apply evenly – brush, roller, or spray for uniform thickness.

- Build layers – apply 2–3 coats for maximum protection.

- Test insulation – verify kV resistance before putting back into service.

Conclusion: Protect Your Coils, Protect Your Productivity

Electrical insulation isn’t just about paint on copper. It’s about protecting your equipment, safeguarding your uptime, and ensuring safety.

With MR. JO Electrokot-HB, you’re not just applying a coating—you’re applying reliability, strength, and confidence.

Leave a Reply