MR. JO Tecbond-ELV — Solve Penetration & Insulation Failures in Electrical Assemblies

MR. JO Tecbond-ELV — Solve Penetration & Insulation Failures in Electrical Assemblies

In a busy workshop or warehouse, safety isn’t just about heavy equipment and alarms — it’s about what people can see, avoid, and follow.

And that’s where MR. JO FloorKot-YLW — a bright yellow, high-build epoxy coating — comes in.

More than just a splash of color, this simple-to-apply line marking system helps organize workflows, mark hazards, and create visual safety zones that last longer than tapes or cheap paints.

Why ELV is the right fix

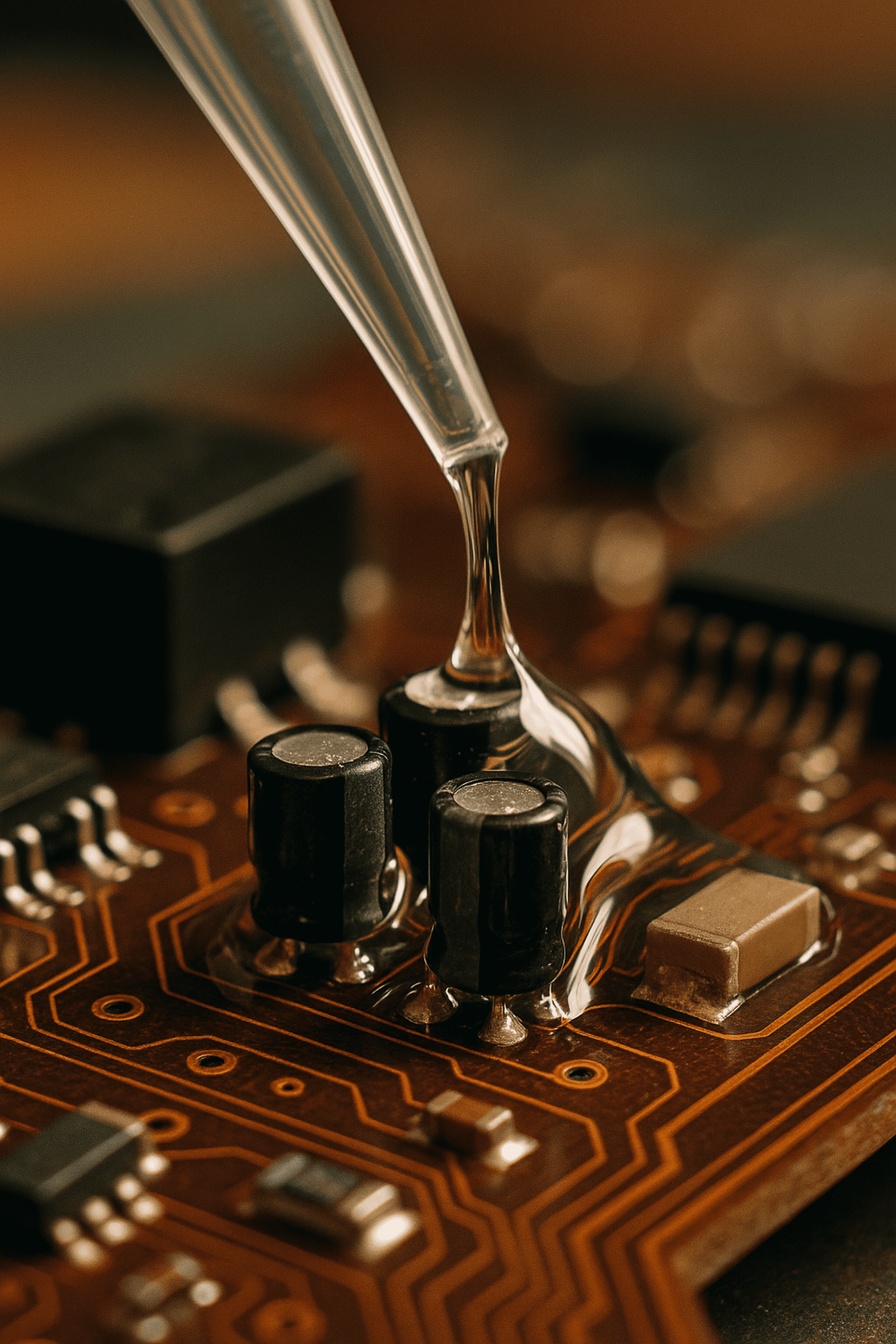

MR. JO Tecbond-ELV is a low-viscosity, 100:10 epoxy system formulated for penetration, wetting and dielectric protection. Its flow-through properties let it reach tight clearances, soak into windings, and encapsulate delicate parts without applying pressure or damaging assemblies.

Real-world use cases

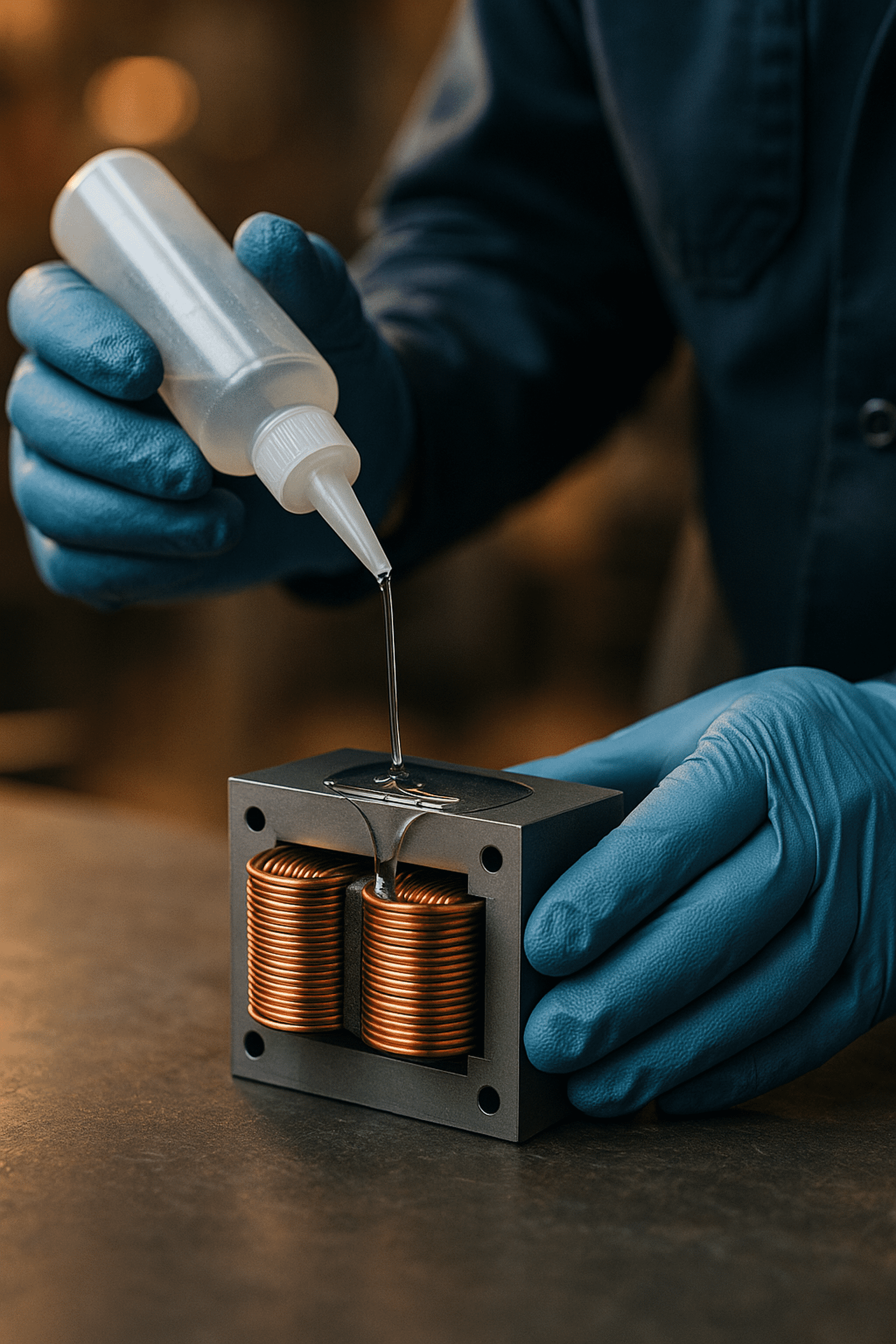

- Impregnating motor & transformer windings to improve insulation and mechanical stability.

- Capillary bonding of shims, micro-gaskets and thin laminations.

- Encapsulation / potting of small sensors and precision coils where void-free fill is required.

- Repairing micro-cracks in insulating ceramics or porcelain parts.

How to use — job-ready workflow

- Prep: Clean components — remove flux/grease, dust and moisture. Dry assemblies completely.

- Weigh & mix: Use a scale — 100 (resin) : 10 (hardener) by weight. Mix thoroughly until uniform.

- Degas (optional): For critical high-reliability parts, degas mixed epoxy under vacuum to remove entrained air.

- Apply / Impregnate: Use syringe, dip, brush or vacuum impregnation. Let capillary action draw ELV into windings and gaps.

- Cure: Allow to cure per TDS. For best electrical performance, consider a controlled post-cure if recommended.

- Inspect & finish: Check for voids or runs; remove excess before cure hardens.

Dos & Don’ts

Do:

- Use small batches for vacuum impregnation to avoid exotherm.

- Work in a dry environment — moisture reduces electrical insulation performance.

- Degas when required for mission-critical parts.

Don’t:

- Don’t let mixed resin contact live terminals — mask off contacts first.

- Don’t mix large batches in hot ambient conditions (exotherm risk).

- Don’t assume “more” gives better insulation — void-free placement matters more than volume.

Troubleshooting

- Bubbles after cure? Likely trapped air — use vacuum degassing and slow, controlled impregnation.

- Epoxy creeping onto contacts? Mask contacts or use a grease stop; apply ELV with precise dispensers.

- Slow cure in cold rooms? Move assembly to recommended cure temp or use gentle post-heat.

Bottom line

If your problem is getting adhesive into very small gaps, windings or delicate assemblies without bridging or voids, ELV is the targeted solution — it penetrates where others cannot and gives reliable dielectric protection.

Leave a Reply