MR. JO Tecbond – NSF — Stop the drip, keep the edge neat

The real problem:

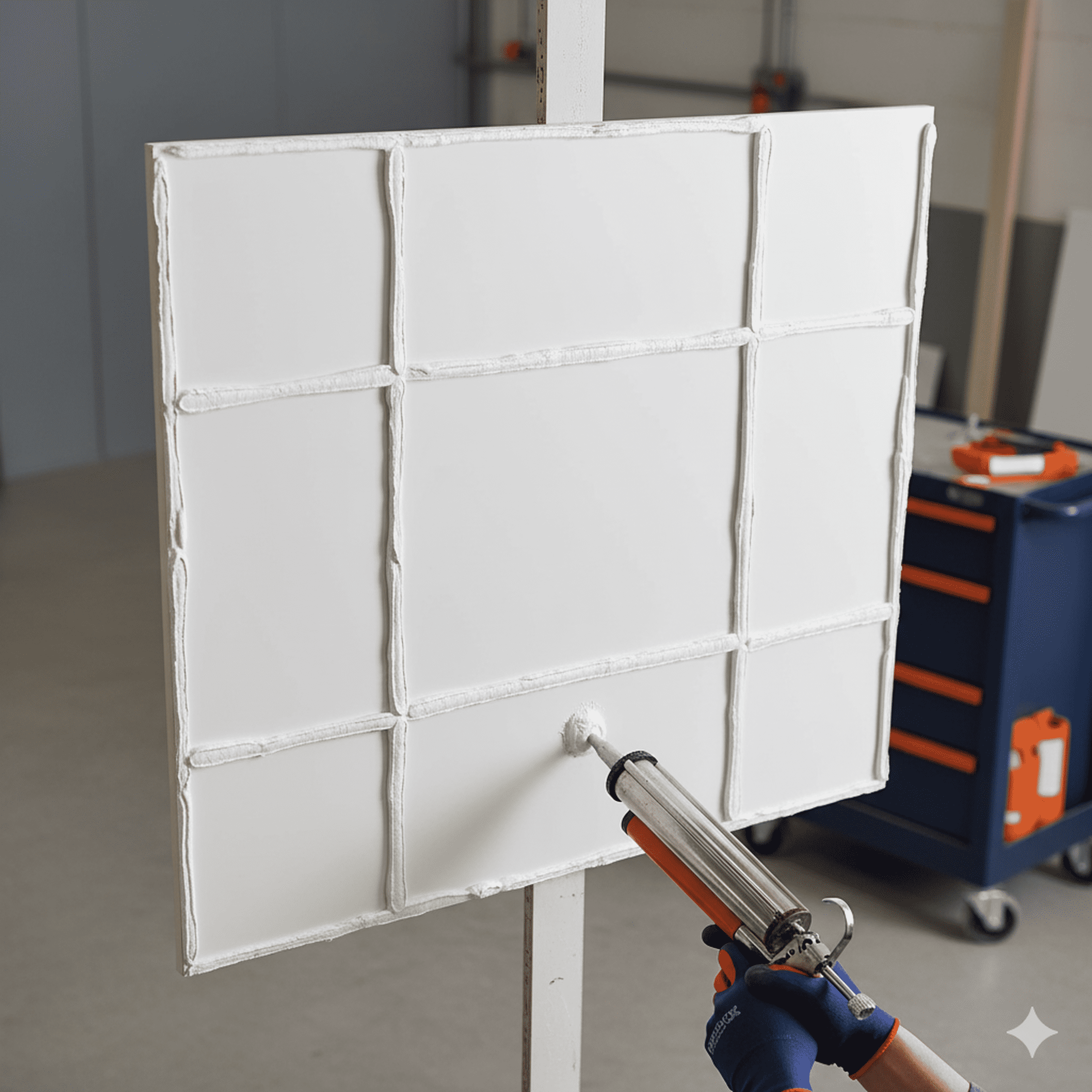

On vertical panels, edges and overhead fittings, conventional liquid epoxies run, drip or spread — leaving messy joints, ruined veneers and extra sanding/clean-up. Installers waste time chasing runs and customers complain about visible finish defects.

The practical solution:

MR. JO Tecbond – NSF is a thixotropic, putty-paste epoxy designed to stay where you place it (non-sag / non-drip) while delivering a strong, durable bond on synthetic wood, laminates, veneers and mixed substrates. It mixes 100:100 by weight and gives a practical working window of about 45–60 minutes at 25°C, so you can work cleanly on vertical/overhead joints without drips.

Why it fixes the problem :

- Non-drip / non-sag formula — clean edges on vertical and overhead work.

- Putty consistency — fills small voids, grips laminates and veneers without running.

- Water- and oil-resistant cured bond — suitable for indoor fixtures and heavy-use furniture.

Job-ready short workflow:

- Prepare: clean, degrease and abrade the surfaces to expose fresh substrate.

- Measure: weigh Part A : Part B = 100 : 100 by weight. Mix thoroughly for ~2 minutes until uniform.

- Apply: press the putty paste into the joint/edge with a spatula — it will stay put.

- Support: light clamping or edge support for 2–3 hours helps alignment on heavy parts.

- Cure: allow at least 8 hours for initial handling; full cure in ~24 hours at room temp.

On-site tips & troubleshooting:

- If the batch gels too quickly, reduce batch size or work in shaded/cooler areas.

- For glossy laminates pre-abrade with a scotch pad for better wetting.

- Clean tools before the adhesive starts to set.

When you need clean, drip-free bonding on vertical and overhead furniture or panels, choose MR. JO Tecbond – NSF for a neat job done right.

Leave a Reply