How Mr. JO Marblewrap Prevents Edge Breakage and Boosts Slab Yield in Marble Block Cutting

Used Across: Kishangarh, Silvassa, and other leading marble processing clusters

Products: MR. JO Marblewrap & MR. JO Marblewrap-P

🧩 The Problem: Fragile Blocks, Broken Slabs, High Waste

In natural stone processing, especially with marble and soft decorative stones, edge breakage, corner chipping, and micro-cracks during block cutting are everyday challenges. Before slabs even reach polishing, processors lose material, time, and profit due to:

- Unstable edges that crumble during sawing

- Internal cracks that spread under vibration

- Rejected slabs due to visible damage

Worse, typical epoxy pastes either flow out too much, fail to cure fast in cold weather, or are difficult to mix and apply on vertical block surfaces.

⚙️ Product Highlights:

- Multipurpose Formulation

Designed to work across a wide range of surfaces including metal, ceramics, glass, plastics, wood, and composites. - Medium Pot Life for Balanced Work Time

Offers 60–70 minutes of workable time, perfect for controlled assembly and positioning. - High Bond Strength

The tough, non-shrinking bond holds under stress, vibration, and moderate thermal cycling. - Solvent-Free, Safe Application

No unpleasant odor or volatile organic content — safer for use in closed or indoor environments.

🧑🔧 The User: Block Wrapping Teams in Processing Yards

MR. JO Marblewrap and Marblewrap-P are widely used by marble block processing units just before cutting. The users are trained in epoxy handling and familiar with:

- Accurate weight-based mixing

- Adjusting batch size based on ambient temperature and pot life

- Spreading adhesive evenly with a trowel

- Handling glass cloth reinforcement over vertical and side surfaces

This manual but skilled process plays a crucial role in preventing wastage during cutting.

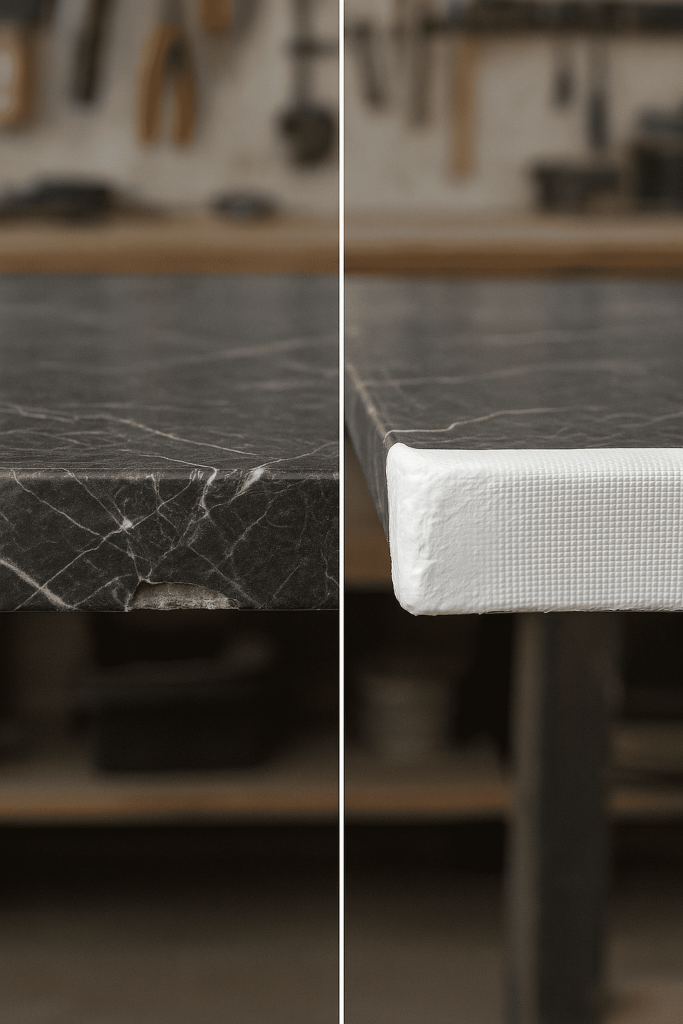

The Application: A Simple, Reliable 3-Layer Process

Surface: 4 vertical sides of the marble block (before cutting)

Curing Time: 24–48 hours at room temperature

Quantity Used: Approx. 30–40 kg per block

✳️ Process Steps:

- Mix MR. JO Marblewrap or Marblewrap-P in 100:100 ratio by weight

- Apply a base layer using a trowel over the block surface

- Wrap glass cloth over the wet adhesive

- Apply a final layer of Marblewrap over the cloth to fully impregnate

- Allow to cure before cutting the block into slabs

Color Choices:

- Marblewrap: White, ideal for darker or colored marble

- Marblewrap P: Extra-bright white, perfect for white or light-colored stone

- On-site tinting with epoxy-compatible pastes ensures perfect shade matching

📈 The Result: Cleaner Cuts, Stronger Slabs, Zero Flowout

Once cured, the wrap forms a rigid epoxy-reinforced shell that holds the block together during slicing. The coating doesn’t sag or drip — even at 4–6 mm thickness — ensuring:

- No gaps or voids in vertical wrapping

- Clean slab edges with reduced micro-chipping

- Higher usable area per slab

- Time-saving due to soft, easy-to-spread consistency

- Better operator confidence with easy mixing and predictable results

User Feedback:

“Very easy to apply and doesn’t run. No refilling needed. Matching shades is simple. Packing is user-friendly and there’s almost no waste.”

🧪 Technical Edge: How It Stands Out

Compared to other block adhesives:

- MR. JO Marblewrap offers excellent adhesion and fast cure — even in colder weather

- The material blends well with natural textures and stone grain

- Unlike traditional pastes, there’s no flowout or cracking during cure

- Coverage is better, thanks to soft thixotropic consistency

- When compared in performance to leading brands like Tenax Rock A+B, MR. JO Marblewrap stands taller in ease of use, spreadability, and field convenience

🔗 Paired Products for Complete Stone Reinforcement

After cutting:

- MR. JO Marblefill is used to fill fine cracks in the resulting slabs

- For full surface epoxy enhancement:

- Use MR. JO Artcast CC33 (heat-cured for maximum clarity)

- Or use MR. JO Marblekot for faster, room-temp epoxy sealing and enhancement

Together, these create a comprehensive system for block-to-slab epoxy protection, from block wrapping to crack filling to surface enhancement.

✅ Conclusion

If you’re in the business of processing premium marble, the transition from block to slab is a make-or-break step — literally. MR. JO Marblewrap and Marblewrap-P provide the strength, convenience, and finish quality needed to reduce waste and boost output.

Whether you’re cutting Makrana white or Silvassa beige, you now have a block adhesive system that works better, faster, and cleaner — just like MR. JO would promise.

Leave a Reply