Clear, Strong, Smooth: How MR. JO Marblekot Turns Porous Marble Slabs into High-Gloss Masterpieces

Used Across: Marble processing units in Rajasthan, Silvassa, and other marble hubs

Product: MR. JO Marblekot – a two-component, clear epoxy coating system

🧩 The Problem: Hairline Cracks, Dull Surfaces & Rejected Slabs

Marble slabs—especially those from porous or delicate blocks—frequently suffer from:

- Hairline cracks invisible to the eye but damaging during polishing

- Surface dullness caused by open pores

- Dusty or brittle layers that weaken structure

For processors, these issues mean lower slab quality, more rework, and wasted time and effort. Traditional polyester sealers often yellow, shrink, or lift during polishing. A better solution was needed — one that strengthens, seals, and enhances without extra steps or equipment.

⚙️ Product Highlights:

- Multipurpose Formulation

Designed to work across a wide range of surfaces including metal, ceramics, glass, plastics, wood, and composites. - Medium Pot Life for Balanced Work Time

Offers 60–70 minutes of workable time, perfect for controlled assembly and positioning. - High Bond Strength

The tough, non-shrinking bond holds under stress, vibration, and moderate thermal cycling. - Solvent-Free, Safe Application

No unpleasant odor or volatile organic content — safer for use in closed or indoor environments.

🧑🔧 The User: Marble Processors Needing Reliability and Speed

MR. JO Marblekot is widely adopted by marble processors who seek:

- A solvent-free, low-odor coating

- A product that cures at room temperature, even in cooler climates

- One product that seals, strengthens, and beautifies in a single step

It is especially useful in medium-scale and traditional slab units, where quick turnaround and manual application matter.

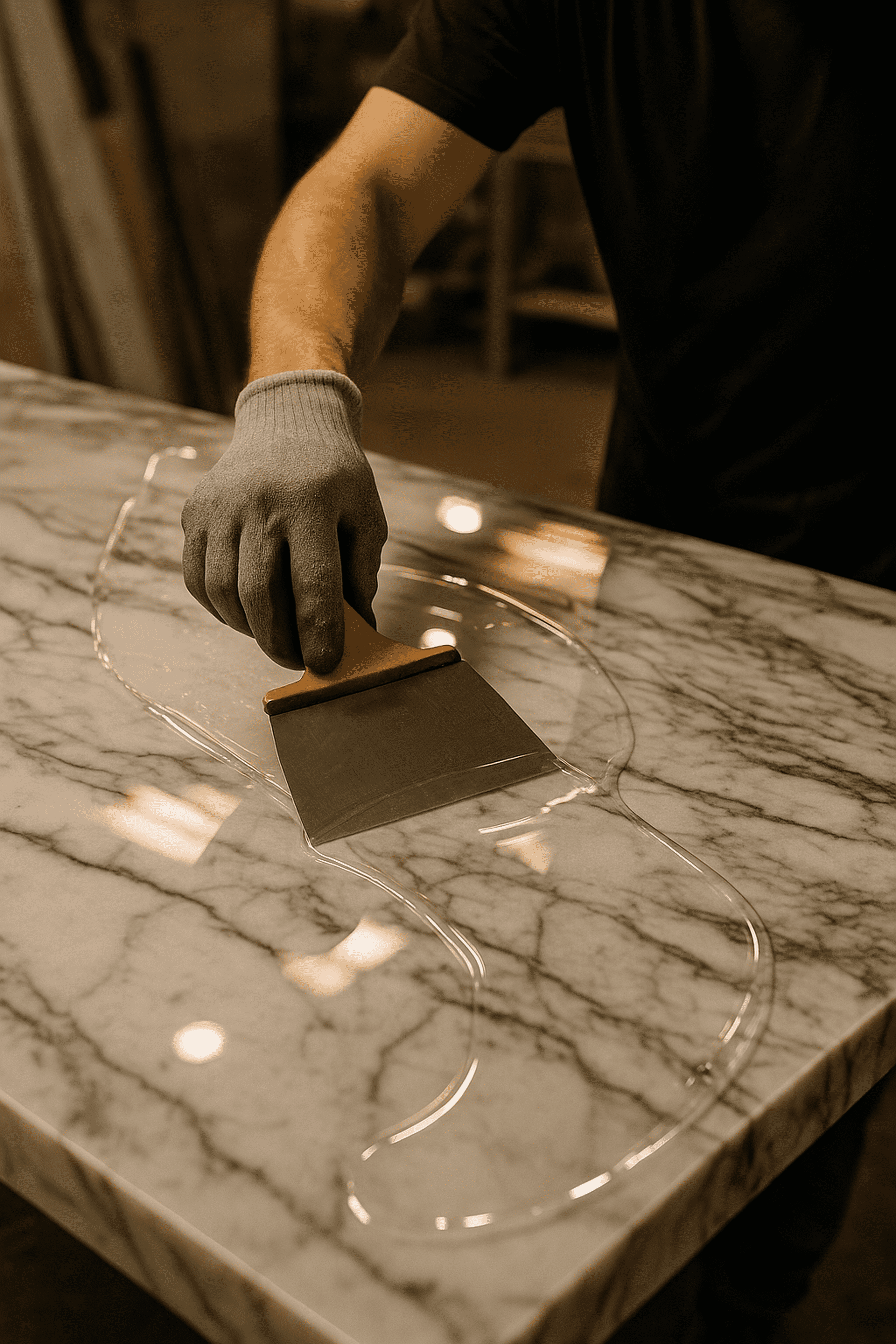

🛠️ The Application: Coat, Cure, Polish — Done.

Surface: Entire marble slab (before final polishing or dispatch)

Purpose: Crack-filling, porosity sealing, full-slab coating

Application Tools: Brush or trowel

Curing: Room temperature (24 hours typical)

Coverage: ~5–6 m² per kg mix, depending on porosity

✅ Step-by-Step:

- Mix resin and hardener in a 100:50 PBW ratio

- Apply directly over clean, dry marble surface using brush or trowel

- Allow to cure naturally (no oven required)

- Proceed to final polishing or dispatch

Optional Tinting: Epoxy-compatible dyes or pigments may be added to match stone shade.

📈 The Result: Fewer Defects, Higher Gloss, Stronger Slabs

Processors using MR. JO Marblekot consistently report:

- Invisibly filled cracks with no re-opening during polishing

- Smooth, dust-free finish that retains gloss

- Consistent shine across the entire slab

- Improved surface strength, reducing chipping and waste

User Feedback:

“MR. JO Marblekot flows easily, gets into fine pores, and gives a rich gloss. It doesn’t lift or come off during polishing like cheaper sealers. Easy to mix, and no smell or solvent problems.”

🧪 Technical Advantage: Built to Outperform Polyester Sealers

- Low viscosity ensures deep pore penetration

- All-weather curing — works reliably even in winter

- No shrinkage or surface dullness

- Solvent-free, making it safe for users and stone alike

- Polishing-friendly — doesn’t gum up pads or create drag

Compared to traditional polyester coatings or imported alternatives, Marblekot delivers a cleaner finish and longer durability — at a more accessible price and easier application.

🔗 Paired Products: A Complete Slab Enhancement System

Before Marblekot:

- MR. JO Marblewrap (or Marblewrap-P) is used to reinforce blocks before cutting

- MR. JO Marblefill is used for major crack filling if needed

After Marblekot:

- Slabs can be polished and shipped

- In fully automated units, MR. JO Artcast-CC33 may be used as an alternate heat-cured system

✅ Conclusion

Whether you’re dealing with porous marble, minor cracks, or uneven gloss, MR. JO Marblekot offers a simple, brush-on solution that strengthens and enhances every slab — without yellowing, lifting, or wasting time.

It’s the clear choice for processors who want their marble to stand out, stay smooth, and shine through.

Leave a Reply