MR. JO Antistatic Flooring System : Static-Safe Flooring Solutions for Critical Workspaces

MR. JO Antistatic Flooring System : Static-Safe Flooring Solutions for Critical Workspaces

In today’s advanced manufacturing, electronics, pharmaceutical, and defence environments, electrostatic discharge (ESD) isn’t just a technical issue — it’s a safety hazard. Even the slightest static spark can damage sensitive electronics, ignite flammable substances, or trigger data corruption.

The MR. JO Antistatic System is engineered to neutralize this risk through a range of electrically dissipative epoxy systems that combine industrial-strength flooring with ESD control.

Our complete solution includes primers, coatings, and self-leveling floor systems that integrate seamlessly, forming a resilient, static-safe envelope for your facility.

🔰 System Overview

| Product | Type | Build Thickness | Resistance (Ohms) | Application Level |

| MR. JO Primer – AS | Primer (2-part) | ~150–200 µm | ≤ 10⁹ | Base for all AS systems |

| MR. JO Floorkot – AS | Coating (2-part) | ~200–250 µm/coat | ≤ 10⁹ | Moderate traffic areas |

| MR. JO Floor – ASL1 | Self-level (3-part) | 1 mm | ≤ 10⁹ | Light traffic, cleanrooms |

| MR. JO Floor – ASL2 | Self-level (3-part) | 2 mm | ≤ 10⁹ | Heavy traffic, ESD zones |

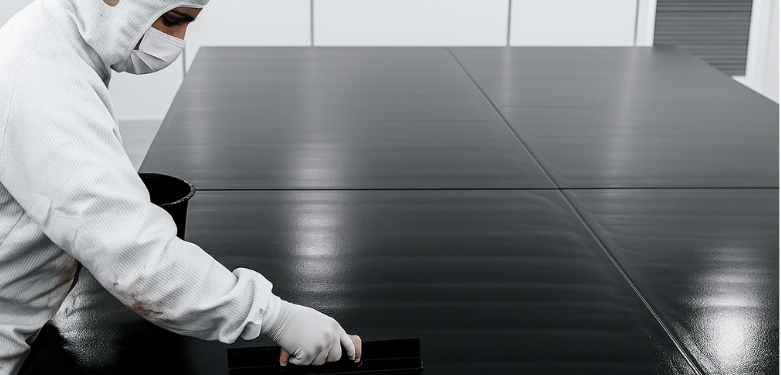

System Build-Up

Each antistatic system follows a consistent structure for optimal performance:

- Surface Preparation

Substrate must be structurally sound, dry, and dust-free. If surface irregularities or thickness buildup are required, use a suitable MR. JO Underlay (e.g. MR. JO Underlay FLO, CMR, TMP) for leveling. - Conductive Grid

A copper tape grid is applied either below or embedded within the MR. JO Primer – AS layer, connected to proper earthing. This ensures a continuous discharge path for static electricity. - Antistatic Primer: MR. JO Primer – AS

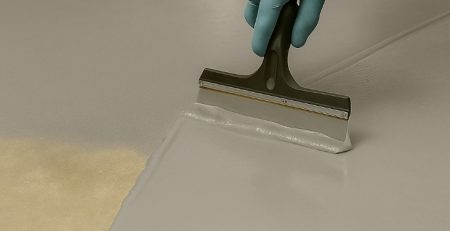

A black, thixotropic, solvent-free epoxy primer that provides a dissipative base layer with excellent adhesion and conductivity. - Top Coat Options:

- MR. JO Floorkot – AS: Durable coating for existing leveled floors.

- MR. JO Floor – ASL1: 1 mm self-leveling system for moderate use.

- MR. JO Floor – ASL2: 2 mm self-leveling for high-performance, heavy-duty applications.

🧪 Product Details

🟧 Mr. JO Primer – AS

- Mix Ratio: 100:30 PBW

- Consistency: Thixotropic paste

- Pot Life: 90–120 minutes

- Coverage: ~3 m²/kg

- Resistance: ≤ 10⁹ Ohms

- Color: Black

✅ Ideal as a conductive base coat for all Mr. JO antistatic flooring systems.

🟦 MR. JO Floorkot – AS

- Mix Ratio: 100:20 PBW

- Consistency: Medium-viscosity, flowable liquid

- Pot Life: 25–45 minutes

- Coverage: ~4 m²/kg/coat

- Resistance: ≤ 10⁹ Ohms

- Color: Pigmented

✅ Best for moderate ESD control zones like warehouses, packaging lines, and storage units.

🟨 MR. JO Floor – ASL1

- Mix Ratio: 100:50:75 PBW

- Thickness: 1 mm

- Pot Life: 20–40 minutes

- Coverage: ~1.6 kg/m²

- Resistance: ≤ 10⁹ Ohms

- Color: Pigmented

✅ Designed for cleanrooms, labs, hospitals, and moderate traffic zones needing reliable ESD control and hygiene.

🟥 Mr. JO Floor – ASL2

- Mix Ratio: 100:50:100 PBW

- Thickness: 2 mm

- Pot Life: 20–40 minutes

- Coverage: ~3.2 kg/m²

- Resistance: ≤ 10⁹ Ohms

- Color: Pigmented

✅ Heavy-duty flooring for ESD-critical manufacturing, electronic assembly, aerospace, and explosive environments.

🧭 Selector Guide – What to Use When

| Application Type | Recommended System |

| Coating existing ESD-safe floor | MR. JO Primer – AS + MR. JO Floorkot – AS |

| Cleanroom or pharmaceutical zones | MR. JO Primer – AS + MR. JO Floor – ASL1 |

| Electronics manufacturing or data centers | MR. JO Primer – AS + MR. JO Floor – ASL2 |

| Uneven floors needing leveling | MR. JO Underlay + MR. JO Primer – AS + Top Coat |

⚙️ System Benefits

✅Controlled ESD Resistance: All systems tested to achieve ≤ 10⁹ Ohms surface resistivity.

✅Seamless Integration: Compatible with all MR. JO Underlay and Primer systems.

✅Solvent-Free & Low Odour: Safe for use in enclosed, sensitive environments.

✅Durable and Hygienic: Moisture-resistant and easy-to-maintain epoxy finish.

✅Versatile Colors: Pigmented options available for visual zoning and safety.

📦 Packaging & Coverage

| Product | Pack Size (A + B + C) | Coverage |

| MR. JO Primer – AS | 5 + 1.5 kg | 4 m²/kg |

| MR. JO Floorkot – AS | 5 + 1 kg | 4 m²/kg/coat |

| MR. JO Floor – ASL1 | 5 + 2.5 + 3.75 kg | 1.6 kg/m² |

| MR. JO Floor – ASL2 | 5 + 2.5 + 5 kg | 3.2 kg/m² |

🔒 Applications Across Industries

- Electronics assembly lines

- Cleanrooms and pharmaceutical manufacturing

- Defence and explosives handling areas

- Data centers and server farms

- Packaging areas for ESD-sensitive components

- Aerospace production zones

🧯 Installation & Caution Notes

- Do not apply if substrate temp is below 15°C.

- Ensure correct earthing through copper tape grid and grounding point.

- Allow full 7-day cure before subjecting to traffic.

- Test conductivity after installation to confirm ESD compliance.

- Maintain clean footwear protocols in sensitive ESD areas.

🏁 Conclusion

The MR. JO Antistatic Flooring System is your go-to solution for complete ESD-safe infrastructure. Whether you need a quick coating over an existing surface or a complete self-leveling build-up from scratch, our tailored systems meet your performance, safety, and budget requirements — all backed by the power to protect, and the strength to bond.

Leave a Reply