MR. JO Floorkot – AS : Electrostatic Dissipating Epoxy Floor Coating

MR. JO Floorkot – AS : Electrostatic Dissipating Epoxy Floor Coating

For environments where static electricity poses a safety risk or can disrupt precision operations, ordinary epoxy coatings are simply not enough. MR. JO Floorkot – AS is a high-performance, solvent-free antistatic epoxy coating developed specifically to dissipate static build-up and provide lasting protection.

With resistance values up to 10⁹ Ohms, it safely channels static charges and prevents dangerous discharge — making it ideal for ESD-sensitive zones. It offers a seamless, durable, and chemical-resistant surface, designed for safety and reliability in demanding workspaces.

Key Applications

MR. JO Floorkot – AS is suitable for use as a final coating in facilities such as:

- Electronics manufacturing and assembly plants

- Clean rooms and semiconductor labs

- Pharmaceutical production and packing

- Automobile paint booths

- Ammunition and ordnance handling zones

- Battery manufacturing units

- Server rooms and high-tech data centers

- Warehouses storing flammable or sensitive goods

Product Highlights

- Antistatic Protection

Reduces risk of spark-related accidents and equipment interference by dissipating electrostatic charge efficiently.

- Solvent-Free, Medium Viscosity System

Applies easily using a roller, brush, or airless spray, creating a high-build, smooth, and non-porous surface.

- Strong Surface Protection

Offers excellent mechanical strength, abrasion resistance, and chemical durability, even in high-traffic zones.

- Pigmented System

Comes in standard industrial colors. Custom color options available on request to suit design or zoning requirements.

- Compatible with Full Antistatic System

Best results when applied over MR. JO Primer – AS and used alongside ASL flooring options for a complete antistatic system.

Technical Details

| Property | Value |

| Color | Pigmented |

| Mixing Ratio (A:B) | 100:20 PBW |

| Pot Life (@25°C) | 25–45 minutes |

| Consistency | Flowable liquid |

| Coverage | Approx. 4 m²/kg/coat |

| Surface Finish | Smooth, even, and opaque |

| Electrostatic Resistance | ≤ 10⁹ Ohms |

Application Method

- Surface Preparation

- Ensure the substrate is clean, dry, and free from dust, oil, or laitance.

- Apply over MR. JO Primer – AS for optimal static dissipation.

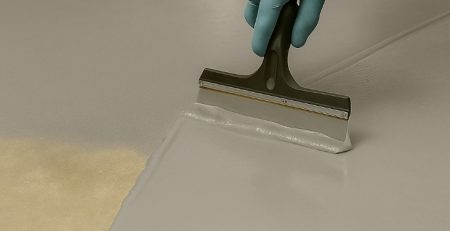

- Mixing & Application

- Mix components A and B thoroughly by weight (100:20 PBW).

- Apply using roller or brush in two coats, ensuring even spread.

- Copper Tape Grid Recommendation

- Install copper tape grid below the Primer-AS layer or directly on the substrate before the antistatic primer is applied.

- Connect grid to an earth point to complete the conductive path.

- Curing

- Allow each coat to dry as per specified intervals.

Avoid foot or machine traffic for at least 48 hours, and allow full cure for 7 days for best performance.

Where It Fits in the Antistatic System

- Primer Layer: MR. JO Primer – AS

- Topcoat Option: MR. JO Floorkot – AS (for coating finish)

- Alternative Topcoats: MR. JO Floor – ASL 1 or ASL 2 (for self-leveling finish)

- Optional Underlay: For uneven surfaces or buildup >1 mm, use flowable underlay + standard primer (e.g., MVC, LVC), then proceed with AS primer and coating.

Why Choose MR. JO Floorkot – AS?

Because safety and performance should never be compromised. Floorkot – AS offers peace of mind with every step, shielding your operations from the risks of static discharge, while delivering durability and ease of maintenance for years to come.

Leave a Reply