When Precision Bonds Matter – The Hidden Hero Behind Metal Frames, Rackets & Engineering Fixtures

Solving high-impact bonding challenges with MR. JO Tecbond – OPT

🎯 The Problem:

In many industries, especially in metal sports equipment, engineering jigs, and metal-framed fixtures, there’s a repeated challenge:

How do you reliably bond parts under mechanical stress or vibration without bulky welds or screws – and without worrying about detachment or brittle joints over time?

Traditional adhesives fail in one of three ways:

- They sag or drip during application.

- They can’t hold up to impact or vibration.

- They crack or shrink on curing – weakening the bond.

- For manufacturers, especially in metal badminton rackets (T-joint bonding) or lightweight structural frames, this means:

- Increased returns or repairs

- Manual reworking

- Poor user perception and potential brand damage

✅ The MR. JO Solution:

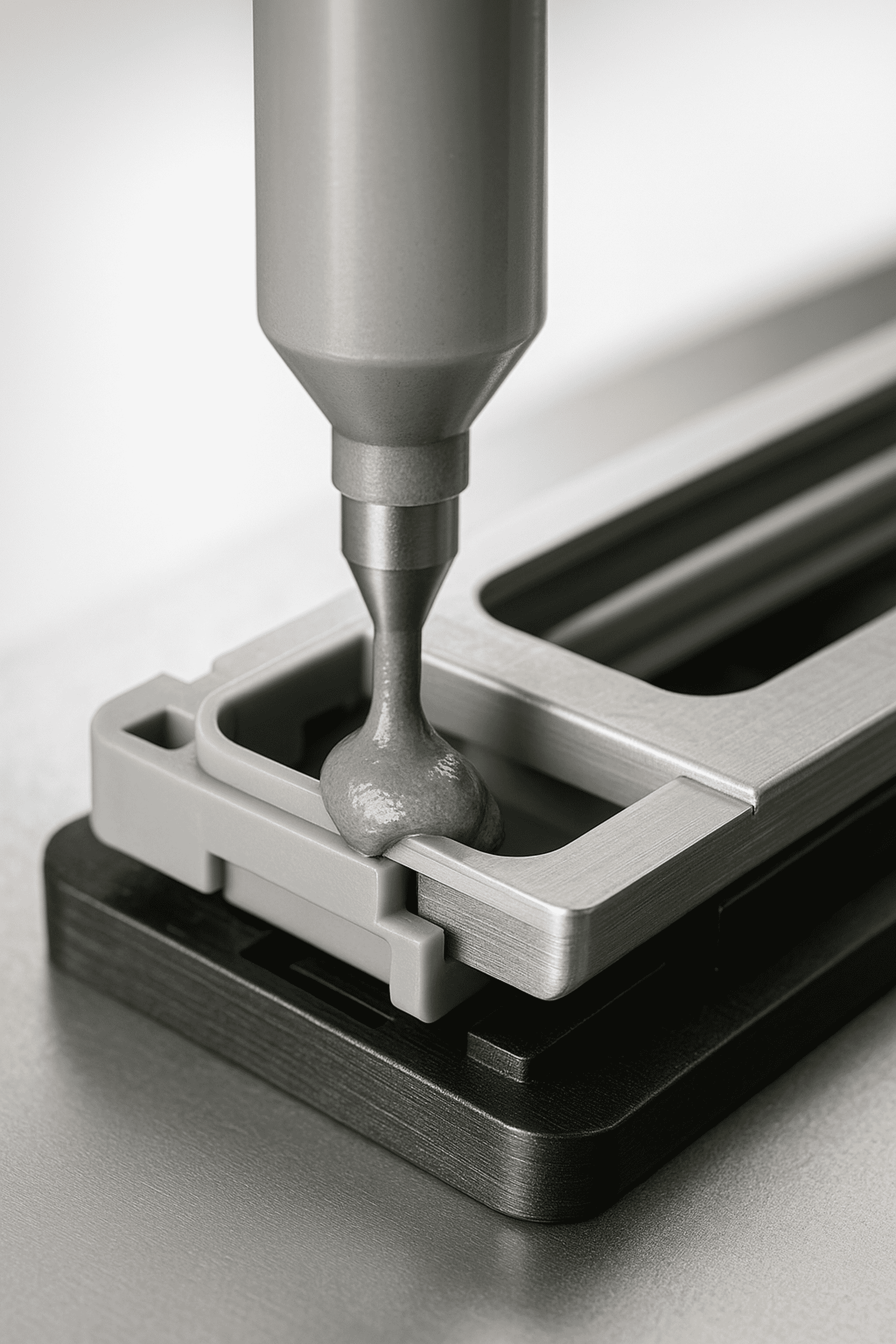

MR. JO Tecbond – OPT is designed as a thick, paste-like, solvent-free epoxy adhesive – engineered to offer superior impact resistance, strong grip on metals, and precision application without flow.

It’s the kind of glue that stays where it’s placed, even on vertical or angled surfaces, while curing to a shock-absorbing, toughened bond.

Why it works so well:

- High viscosity: no drip or flow

- Excellent metal adhesion: ideal for T-joint bonding, tubular structures

- Available in custom colors: grey-white, sky blue, beige, red

Strong cure performance: can be shaped, filed, or machined after curing

🧪 Product Properties at a Glance:

- Color: Available in Grey-white, Beige, Red, Sky Blue (custom on request)

- Pot life: ~90–120 mins @ 25°C

- Mixing Ratio: 100:80 PBW

- Consistency: Paste – very high viscosity, thixotropic

- Optics: Opaque

- Cure: Room temperature or assisted oven cure for faster turnaround

- Post-cure: Machinable, sandable

🔧 Where It’s Used:

- Badminton & squash racket manufacturers – bonding T-joints

- Metal fixture assembly – bonding without rivets

- Reed and textile machinery components

- Industrial jigs, dies, and metal part holders

🛠️ How to Use It:

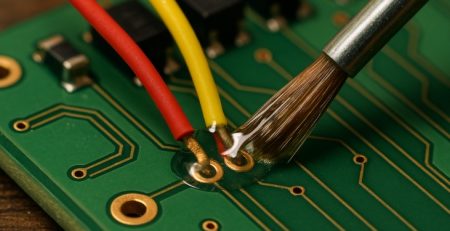

- Surface Prep:

Clean both bonding surfaces thoroughly. Degrease using IPA or acetone. Light sanding improves grip. - Mixing:

Mix Part A and Part B in 100:80 ratio by weight until fully uniform. Avoid entrapping air. - Application:

Apply with spatula or blade. Position and clamp if needed. - Curing:

Leave undisturbed at room temperature. For faster cycles, use a 50–60°C oven.

🧠 Tips & Best Practices:

- Can be loaded with fillers (like quartz or stone powder) for custom properties.

- Excellent for gap filling, since it doesn’t shrink on curing.

- Choose color variants for brand identity or visual inspection purposes.

🆚 Why Choose OPT Over Others?

| Criteria | MR. JO Tecbond-OPT | Generic Epoxies |

| Sag resistance | ✅ Excellent | ❌ May flow |

| Post-cure machining | ✅ Sandable | ⚠️ May crack |

| Metal bonding | ✅ Very strong | ⚠️ May delaminate |

| Application viscosity | ✅ High control | ⚠️ Drips or slumps |

MR. JO Tecbond – OPT is the adhesive equivalent of a metalworker’s vice grip — strong, unmoving, and versatile. Whether you’re fixing a frame, building a T-joint in sports gear, or assembling light fixtures — it does the job with zero drama and total dependability

Leave a Reply