MR. JO Self-Level Epoxy Floors: Choosing Between Eco, SL & CRSL

MR. JO Self-Level Epoxy Floors: Choosing Between Eco, SL & CRSL

When it comes to self-level epoxy flooring, one size doesn’t fit all.

From cost-effective upgrades to high-gloss finishes and chemically aggressive environments — Mr. JO offers three tailored epoxy self-level systems:

- EcoFloor – Smart on budget, strong on performance.

- Floor-SL – The original high-gloss hero.

- Floor-CRSL – Protection for the chemically challenged.

So how do you choose?

🧱 Core Similarities

Before we dive into the differences, let’s look at what’s common across all three:

✅Self-leveling epoxy floors

✅Mix Ratio: Part A : B : C = 100 : 50 : (as per thickness)

✅Thickness Options: 0.5 mm, 1 mm, 2 mm

✅High abrasion resistance

✅Compatible with full MR. JO system (primers, underlays, pigments)

✅Custom tinting via MR. JO ArtPigment

✅Recommended Underlay for 0.5 & 1 mm applications

🔍 Side-by-Side Comparison

| Feature | EcoFloor | Floor-SL | Floor-CRSL |

| Flagship Use | Value engineered flooring | High-gloss premium finish | Chemically resistant environments |

| Gloss Finish | Medium to Good | High | High |

| Hardness | High (especially SLS version) | High | High |

| Abrasion Resistance | Very Good (SLS > SLB > SLP) | Very Good | Excellent |

| Chemical Resistance | Basic spills | Standard for epoxy | Enhanced for acids, alkalis, solvents |

| Pot Life Options | SLP (60–80m), SLB (40–60m), SLS (80–100m) | ~60–80 minutes | ~60–80 minutes |

| Curing Time (Full) | 7 Days | 7 Days | 7 Days |

| Recommended Underlay | Eco (preferred), STD, FLO | STD, FLO, TMP | CMR (preferred), STD, TMP |

| Recommended Primer | Eco Primer (or UPS, MVC, LVC based on substrate) | MVC, LVC, UPS | MVC, LVC, UPS |

| Cost Efficiency | ⭐⭐⭐⭐⭐ (Best Value) | ⭐⭐⭐⭐ | ⭐⭐⭐ |

| Typical Applications | Warehouses, dry process zones, budget-sensitive sites | Malls, hospitals, high-end industrial interiors | Labs, battery rooms, chemical plants, ETPs |

| Tinting / Colors | Yes (via MR. JO ArtPigment) | Yes | Yes |

Thickness & Coverage Details

| System | 0.5 mm | 1 mm | 2 mm |

| Coverage | ~0.8 kg/m² | ~1.6 kg/m² | ~3.2 kg/m² |

| Suggested Use | Light traffic zones | Medium traffic zones | Heavy-duty traffic zones |

🔧 Application & Support System

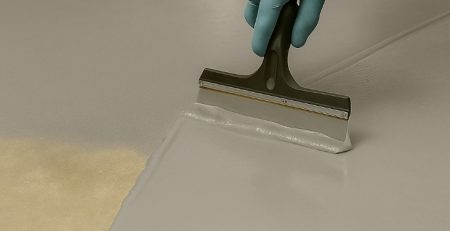

Each of these flooring systems benefits from proper substrate preparation and the right system build.

1. Surface Preparation

- Remove laitance via grinding or shot blasting.

- Repair cracks using MR. JO Tecseal CRP.

- Clean thoroughly (vacuum, degrease if needed).

2. Primers (choose based on surface)

- Eco Primer – Fast setting, budget option.

- UPS – Damp/underprepared surface.

- LVC – Smooth, dense concrete.

- MVC – All-rounder, most recommended.

3. Underlays (especially for thin floorings)

- Eco Underlay – For EcoFloor systems

- STD / FLO – For SL systems

- CMR – For chemical zones (used with CRSL)

- TMP – For tampable covings and heavy thickness build-ups

🛡️ Why It Matters

Picking the right flooring system ensures:

- 🦶 Safer movement zones (anti-slip, seamless)

- 🧼 Cleaner, easier-to-maintain surfaces

- 🔬 Resistance to spills, abrasion, heavy loads

- 💸 Long-term cost savings by avoiding premature wear

✅ Quick Recommendation Guide

| Your Requirement | Pick This System |

| Budget-friendly flooring | EcoFloor-SLP |

| Showroom-like finish & gloss | Floor-SL |

| Acid/solvent-resistant flooring | Floor-CRSL |

| Fast pot life for cold/urgent sites | EcoFloor-SLB |

| Higher abrasion resistance & hardness | EcoFloor-SLS |

| Custom-colored high-traffic industrial floor | Any – with ArtPigment |

With MR. JO Self-Level Epoxy Floor Range, you don’t have to compromise between price, performance, or polish.

Whether it’s a budget-smart upgrade with EcoFloor, a glossy statement with Floor-SL, or chemical armor with Floor-CRSL, there’s a system engineered for your floor’s purpose.

Leave a Reply