When Your Epoxy Floor Needs Muscle and Class

When Your Epoxy Floor Needs Muscle and Class

In industrial flooring, aesthetics and durability are often treated as trade-offs. But what if you could have both?

Introducing MR. JO Floor-CRSL — the chemical-resistant self-leveling epoxy floor designed for industries where spills are routine, reactions are risky, and failure is not an option.

This isn’t just an epoxy floor—it’s defense with gloss, protection with polish, and endurance with elegance.

💎 Where Performance Meets Protection

Mr. JO Floor-CRSL is built using advanced epoxy resins and hardeners selected for chemical resistance, while maintaining all the visual and smoothness benefits of a traditional self-level epoxy floor.

It’s the ideal solution for:

🧪 Laboratories & Testing Facilities

🏭 Chemical Processing & Storage Areas

💊 Pharmaceutical Manufacturing Units

🧼 Food & Beverage Zones with harsh CIP chemicals

🧯 Battery Rooms, Fuel Additive Units

🔬 R&D Centers handling acids, alkalis, and solvents

⚙️ Thickness & Coverage Options

Offered in three grades based on required thickness and usage:

| Product | Typical Use Area | Thickness | Coverage (Approx.) |

| CRSL0.5 | Cleanrooms, ESD labs, dry zones | 0.5 mm | ~0.8 kg/m² |

| CRSL1 | Pharma mfg., cosmetic labs, test areas | 1 mm | ~1.6 kg/m² |

| CRSL2 | Battery banks, tanks, containment floors | 2 mm | ~3.2 kg/m² |

Mix Ratio:

Part A : Part B : Part C = 100 : 50 : (Filler as per thickness)

Neutral base allows color tinting via MR. JO ArtPigment for custom finishes.

🧱 Surface Preparation & System Recommendations

Surface Prep is Key:

As with all high-performance coatings, the base must be clean, sound, and prepared properly.

- Grinding/Shot Blasting – Remove laitance & contaminants

- Vacuum Cleaning – Zero dust tolerance

- Crack Repair – Use Mr. JO Tecseal CRP for filling

Primer (based on surface condition):

- MR. JO Primer-UPS : For damp, moist, underprepared substrates

- MR. JO Primer-LVC : For tight/smooth concrete

- MR. JO Primer-MVC : General use, most preferred

- MR. JO EcoPrimer : Fast setting and moisture-tolerant

Underlay Suggestions (especially for 0.5 & 1 mm):

- MR. JO Underlay-CMR : Chemical-resistant screed base

- MR. JO Underlay-FLO or STD : For smoothness and screed levelling

- MR. JO Underlay-TMP : For thick screed or coving zones

💧 Chemical Resistance Snapshot

| Chemical | Resistance |

| Hydrochloric Acid (10%) | Excellent |

| Sulfuric Acid (30%) | Excellent |

| Sodium Hydroxide (30%) | Excellent |

| Lactic Acid (10%) | Good |

| Xylene, Toluene | Moderate to Good |

| Sea Water | Excellent |

| Alcohols & Solvents | Moderate to Good |

🛠️ Application & Curing

| Step | Time (25°C) |

| Pot Life | 60–80 minutes |

| Touch Dry | 12–24 hours |

| Recoat Window | 2–24 hours |

| Full Cure | 7 Days |

✅ Best Practices

- Always mix components A and B completely before adding filler.

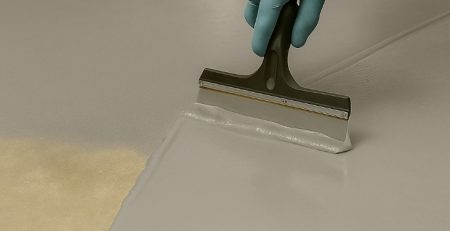

- Use spike roller immediately after pouring for bubble release.

- Work within pot life – don’t extend with water or thinner.

- Add MR. JOArtPigment into Part A and blend before combining with Part B.

🎨 Custom Colors & Finishing Touches

MR. JO Floor-CRSL comes in neutral base, ideal for tinting to any standard or custom color using MR. JO ArtPigments.

It can also be topped with MR. JO Floorkot-CLR clear coat for enhanced gloss and abrasion resistance.

🧩 How It Compares

| System | Strength | Chemical Resistance | Gloss | Cost Efficiency |

| EcoFloor | Very Good | Moderate | Medium | ⭐⭐⭐⭐⭐ |

| Floor-SL | Excellent | Moderate | High | ⭐⭐⭐⭐ |

| Floor-CRSL | Excellent | High | High | ⭐⭐⭐ |

Mr. JO Floor-CRSL is where chemical resistance meets coating class.

Whether you’re designing a high-risk manufacturing zone or a sophisticated testing lab, this system delivers flooring that protects—and impresses.

Ready to upgrade your epoxy game where chemicals are in play?

Leave a Reply